Lean product management is a methodology designed to help organizations bring products to market more quickly by trimming excess and inculcating customer feedback at each step of the development process.

In this guide, we’ll introduce you to the lean methodology, look at a famous example, and explore ways to promote lean thinking in your organization.

The lean startup concept was first coined by Eric Ries, an American entrepreneur and author, in his acclaimed book, The Lean Startup. In the words of Ries:

“The Lean Startup method teaches you how to drive a startup-how to steer, when to turn, and when to persevere-and grow a business with maximum acceleration.”

Each year, 90 percent of startups fail. This is irrespective of industry; the startup failure rate is roughly the same across all verticals. Furthermore, 70 percent of startups fail within the first two to five years. Inefficient methodologies, redundant workflows, and thoughtless organizational structure are some common reasons behind these failures.

Lean refers to delivering value to the customer by eliminating waste. Lean product management means applying lean startup principles to the product development lifecycle.

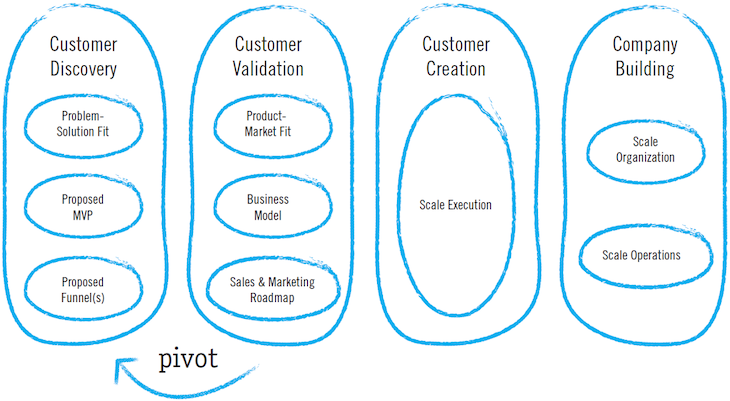

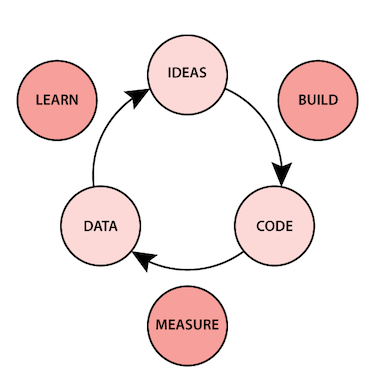

The lean startup methodology recommends developing a minimum viable product (MVP) and then, using the build-measure-learn feedback loop, improving the product further.

Lean product management provides a framework for the product team to continuously test and validate their learning — an important principle of agile software development. Once you embrace this validated learning process, the focus remains on the customer value and thus helps optimize product-market fit.

In the 1930s, Toyota invented the Toyota Production System to eliminate waste and provide the highest-quality product to the customer in the shortest possible time with lowest production cost.

The Toyota Production System was based on two pillars:

How has the lean thinking process worked out for Toyota? In 2000, the auto manufacturer launched 14 new products — more significant than GM’s entire list of products.

Toyota’s continued success has led to the rise of lean thinking across industries, from manufacturing, to retail, to healthcare, construction, etc. Product managers all over the world apply lean principles to the product development process, bringing products to market faster using minimum resources.

Lean product management helps provide structure to the product development process. Among its many benefits, the lean approach helps product teams:

Lean manufacturing aims to reduce waste and eliminate unnecessary processes to optimize production and minimize cost. The decisions made during this process can immediately show results during the manufacturing process. For example, if defective products are making it out of production, a manufacturer might add a quality check to minimize defects.

The product development process is a whole different ball game. The product development lifecycle is a more complex process by which new products are first designed and then built. Required tweaks to a design or feature might not surface until the product has been released to the market.

Let’s dive into the principles of lean product management to understand how this approach can help your team product successful products. Lean product management espouses the four Rs:

The product manager must promote a culture of knowledge sharing within the team.

Documentation must be done for designs, product requirements, analytics, features developed, versions released, etc. This knowledge must be accessible to the entire team.

Other practices such as code commenting and regular training for developers also lend themselves to lean product development.

As per lean (and agile) guidelines, people are the most important part of your organization and, as such, should be fully trusted to plan their own work. All team members must respect each other.

Lean encourages to build and reward competence within teams. Inculcate pair programming to help developers learn from each other and encourage team bonding.

Removing wasteful activities during development (or even features that are not useful to the customer) is a key tenet of lean product development. Lean teams should remove any bugs or defects before releasing a feature. You should also bridge communication gaps between cross-functional teams and stakeholders to build consensus and streamline the decision-making process.

Introduce a customer feedback mechanism to help your team focus on the needs of the customer. The QA team must test builds before release by honing in on customer needs and identify any defects to ensure early resolutions.

Product managers must work with customer success or support teams to get timely feedback from the customers on the new features. This enables them to plan further iterations of the product optimized to customer needs.

Now that we understand the concept of lean product management, how do you apply this way of thinking as a product manager?

You can gradually move toward lean product management by introducing lean practices and engaging the team. Over time, the product team will adopt the change and apply lean thinking while working on their tasks.

Below are some activities that can help you implement lean product management in your organization.

Market analysis is an ongoing activity done during most of the product life cycle. Market analysis is required to keep tabs on changing customer needs and emerging competitors.

Product managers strive to attain product-market fit, not to simply jam products down the market’s throat. Lean product managers in particular know when they need to slow down, analyze product data, and implement any necessary tweaks before releasing a product to the market.

Business process mapping is a visual, step-by-step guide to the business process from beginning to end. In product management, process maps can be used to showcase the process of bringing a product from ideation to implementation and, finally, release.

Each step in the process should be evaluated continually to determine whether any tasks can be eliminated, streamlined, or combined to bring the product to market more quickly.

Value stream mapping is similar to business process mapping. Unlike business process mapping, however, which is more about improving processes, value stream mapping is centered on driving value to the customer.

The lean startup process is all about the build-measure-learn feedback loop. It directs product-driven organizations to ideate and build an MVP and quickly release to market.

Measure the performance of the product, then start working on the next iteration based on the customer feedback. The end goal is to release an optimized product tailored to the needs of the customer.

Learning and documenting lessons is an important part of the process. The aim is to reduce waste, focus on core features, produce a saleable MVP with minimum expense, and iterate continuously.

For product managers, it’s all too tempting to spend resources on features that don’t adequately or accurately address customer needs. Likewise, some organizations operate without a clear product strategy while creating and launching products.

When product teams don’t know exactly why they’re building what they’re building, it’s very difficult to operate according to lean principles and values.

To successfully carry out lean product management, product managers must:

It’s the product manager’s job to think like a customer to discover the problems they face. There are many ways to identify customer problems, such as conducting short surveys, holding focus groups, and monitoring customer reviews and complaints.

The trick is to evaluate which problems are a) most significant and b) affecting the largest number of customers and prioritize the backlog accordingly.

User journeys, reviews, and usage metrics are all valuable data points for product managers to track. You should continuously experiment by introducing new features and monitoring the adoption rate to validate your assumptions. There is always scope to improve an existing feature according to customer feedback.

The product manager must oversee the creation of a roadmap that highlights customer problems and outlines the priority of solutions to align with key stakeholders in the product development process.

A good product manager engages their team to come up with new ideas to help solve customer problems. Instead of working in silos, the product development process is always more efficient (and more enjoyable) when people come together to brainstorm and establish shared goals.

By its simplest definition, lean product management provides a set of guidelines to create successful products.

Boiled down even further, lean product management helps you release the right product at the right time.

Product managers represent the voice of the customer, which should supersede any requirements set by upper management. Aligning leadership with the product roadmap is a crucial task for customer-centric PMs.

Lean product management principles help product managers stay focused on creating customer-centric products while eliminating waste. When done right, the lean methodology helps you support and validate your hypotheses and present your roadmap to leadership in a way that promotes alignment and continuous improvement.

Featured image source: IconScout

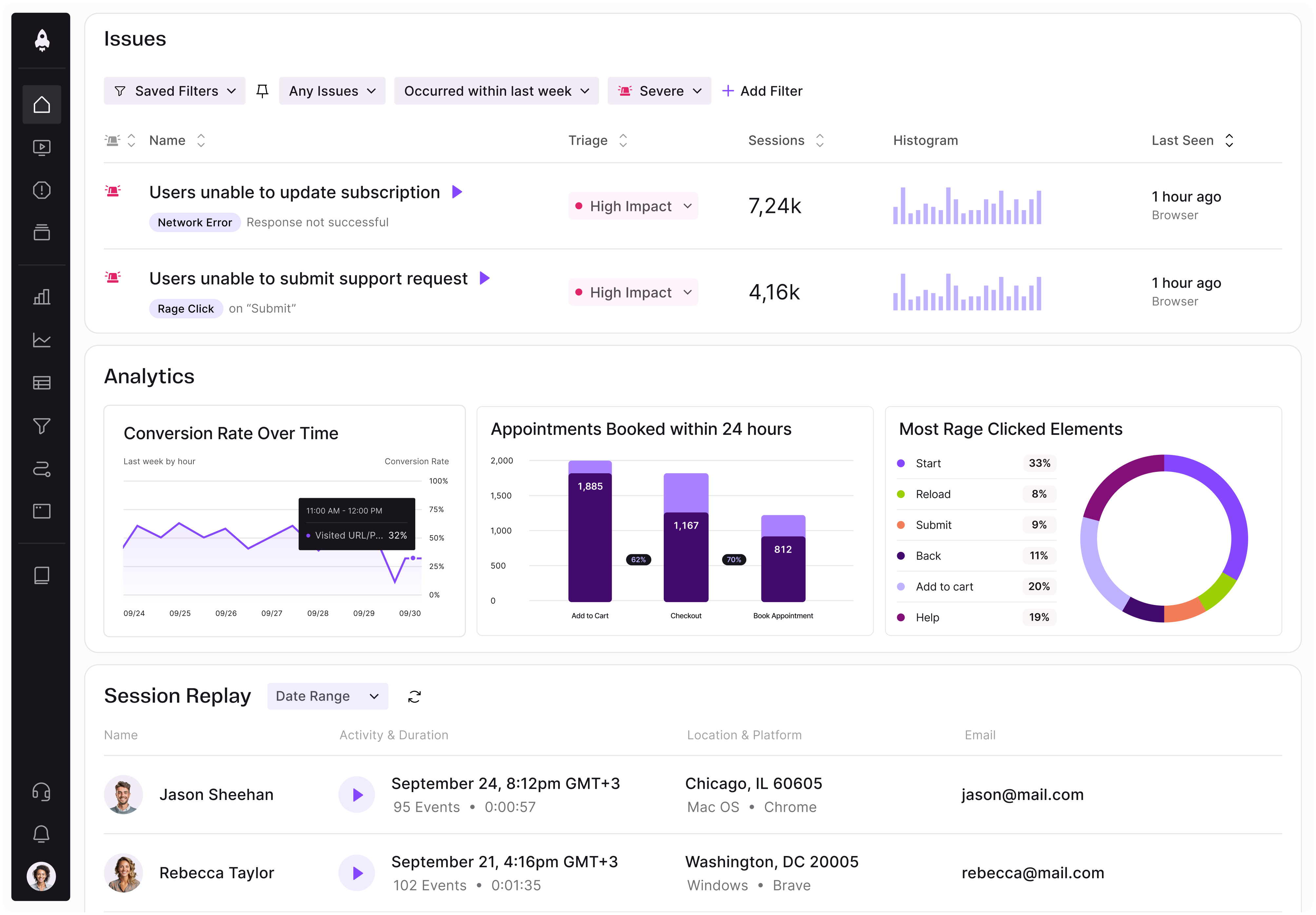

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.

Maryam Ashoori, VP of Product and Engineering at IBM’s Watsonx platform, talks about the messy reality of enterprise AI deployment.

A product manager’s guide to deciding when automation is enough, when AI adds value, and how to make the tradeoffs intentionally.

How AI reshaped product management in 2025 and what PMs must rethink in 2026 to stay effective in a rapidly changing product landscape.