Editor’s note: This blog was updated 20 January 2025 by Sara Nguyen to include a historical background of QFD, an FAQs section, and expanded insights for you to bring back to your product team.

Creating customer-centric products is crucial for success. Quality function deployment (QFD) is a powerful methodology designed to prioritize the voice of the customer (VOC) throughout the product development process. By gathering customer opinions, QFD can turn these insights into a satisfactory product for prospects.

QFD enhances your understanding of customer needs by integrating customer considerations into both product design and development. When done correctly, it reveals the most impactful features to build to improve customer satisfaction.

Ultimately, QFD leads to products that satisfy your customers. By employing a structured approach, QFD accounts for customer needs and preferences. As a result, it increases the likelihood of meeting your target audience’s expectations.

VOC offers valuable insights; however, it wasn’t until the 1960s that quality function deployment was created by Yoji Akao and Shigeru Mizun to effectively translate VOC into specific product features. QFD serves as a framework for identifying significant product features through meticulous analysis of customer feedback.

Several global companies like Ford, Toyota, General Motors, AT&T, and Hewlett-Packard quickly adopted QFD. In recent years, QFD was integrated into the ISO 16355 standard. The series provides guidelines for using QFD to discover product requirements from customer needs.

Before diving into the detailed process of quality function deployment, it’s essential for you to understand its key components. These foundational components of the QFD methodology empower you to analyze and prioritize customer requirements.

This section covers the house of quality, a core tool of QFD, and the voice of the customer (VOC), which lays the groundwork for gathering customer insights.

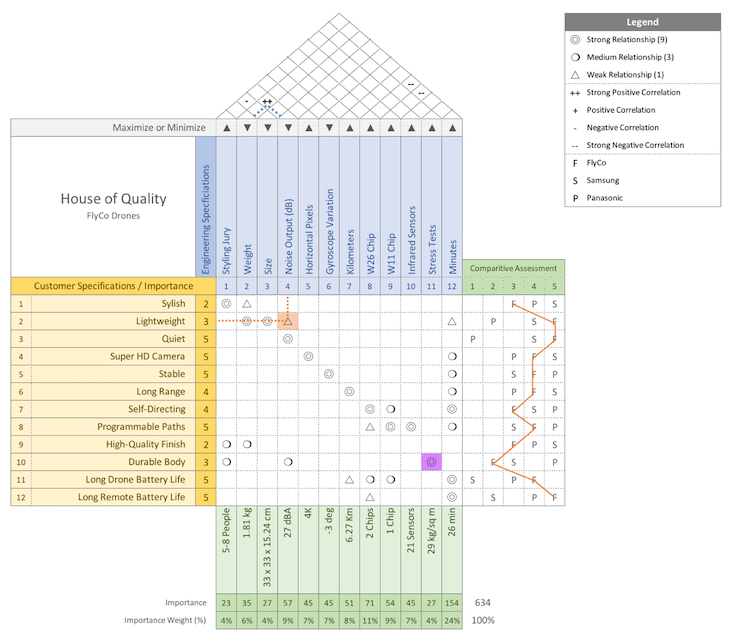

It’s easy to think the house of quality is the same thing as QFD, but it’s actually the core tool of the QFD methodology. It contains several “rooms,” which create a house-shaped matrix:

Source: What Is Six Sigma

There’s no universally accepted version of the house of quality; you’ll see many variations, and it also changes as you move further along the phases of the methodology.

However, there are a few core rooms that frequently appear. Here’s a brief overview of each room:

Before you can build the house of quality — and, subsequently, the entire QFD methodology — you need to identify the voice of the customer (VOC). The VOC summarizes customers’ needs, wants, preferences, and desires associated with a product or service.

To develop the VOC, you need to create a solid market research report. Ideally, you should use a significant sample size to get the most accurate results.

There are a few ways to gather customer feedback to build the VOC. Each offers slightly different benefits. Popular methods include:

Regardless of your method, you should begin the VOC research process by identifying key themes and priorities. As you go through the feedback, you may find a clear feature that your customers want. Other times, you may find themes of what your customers feel like you lack. The analysis can inform the product development and ensure you create a customer-centric product.

Once you determine specific items customers request for, then you can ask the customers how important it is to them to have that item, or you can rank items in order of importance. These items are then listed on the left side of the house of quality matrix, along with a weighted score of importance.

It’s crucial to develop the VOC correctly. Inaccurate information can skew the results of your market research and lead to poor deployment of the QFD.

As mentioned earlier, you may find slight variations in the QFD methodology because there isn’t a universally accepted way to conduct the matrix. However, these four seem to comprise the closest thing there is to a standard model.

Many people tend to only focus on the first phase of the QFD method because this phase directly incorporates customer feedback and finds the relationship between this feedback and product specifications.

However, there are additional phases, and they have a waterfall effect on each other:

Going through all four phases ensures the product development process is optimized at every level. At the end of each phase, the control factors (listed on the top of each matrix) move to the left-hand side of a new matrix and a new set of control factors go on top. This helps identify additional opportunities or conflicts in areas such as design, product development, engineering, and quality control.

The product planning phase begins with gathering customer feedback to develop the VOC. In this phase, you also identify the control factors, which are usually technical requirements. There may also be a competitive analysis to find the strength and weaknesses of your competitors.

Next, identify the relationship between the VOC and technical specifications to pinpoint what features to build next to satisfy customer needs. Ideally, this should be an area where your competitors are weak.

Product planning can help with the following goals:

Once you discover the features that make the most impact, you can start the product development process. To amplify the VOC, update the appropriate teams of the results and the next steps for building the features. One of the steps is to take the technical requirements from this phase and populate them into left room for phase two.

Technical requirements move to the left side of the house of the quality matrix, and a new set of control factors are put on top. The control factors for product development are usually critical parts or product specs.

In the product development phase, the goal is to recognize the key parts or specs to build a feature. It also helps with:

The information from phase two is crucial to determine if you have the resources to develop the product. For example, you may discover you need to hire more designers to ensure consistency and quality.

The next step is to ensure you have the right processes in place to build customer-requested features. Take the critical parts or product specs and move them to the left room to start phase three.

Based on the product and component specifications found in the previous phase, this section identifies processes necessary to build features and deliver functionality. This is crucial information for production and quality teams.

Critical parts or product specs are on the left side of the house of quality matrix, and the control factors are steps to build the product specs. You should determine which process has the best impact on creating the product specs.

This phase may be a good time for identifying verification and validation, including:

At the end of the phase three analysis, you discover which steps and processes have the most impact on building the features.

This stage tends to be more crucial for manufacturing than software development. It’s designed to help you identify the best way to check the quality of the processes identified in the previous phase.

The house of quality matrix is built by putting processes on the right side, and the top section contains control specs. Then, your team can determine which controls are the most useful and create quality targets.

For SaaS companies, this phase can be part of the implementation and continuous improvement. For example:

The phase four analysis can help you confirm if you built a product that resonated with your customers. If not, or if you notice a new trend in the market, you can make adjustments to ensure you’re creating a customer-centric product.

Here is a step-by-step example of how a product team can implement the QFD methodology:

In a SaaS company, customer feedback can be gathered through surveys after interactions or by analyzing product analytics. For example, a workplace communications tool may discover that users don’t know about features because they aren’t easily accessible.

Once important features are identified, put them on the left side of the house of quality matrix. People who use a workplace communications tool might want features like integrations with Google Docs or their project management software.

Don’t forget to add a weighted score to each feature. The score indicates the importance of it to the customer. For example, in the automotive industry, customers may value fuel efficiency more than an entertainment system.

The top of the matrix lists all the control factors. In this product planning phase, it’s usually product specifications or design requirements. In the automotive example, control factors could be engine type, vehicle speed, or safety technology.

In the right room of the house of quality, competitor performance is analyzed against each feature. It’s a weighted score of how competitors are doing compared to the VOC-based features. Weak spots can help drive innovation in that area, especially if customers consider that feature a high priority.

Using the relationship matrix (the main room), analyze how control factors impact customer needs. For example, engine type has a strong relationship with fuel efficiency. The high relationship score guides engineers to focus on optimizing the engine.

Control factors may impact each other. Review the control factors and determine what effect they may have on the other. Going back to the car example, changing the engine type for fuel efficiency may impact the vehicle speed. You may need to determine if a lower speed would have a negative impact on customers before you change the engine type.

Multiply the relationship score with the weighted importance factor of the customer-requested features. Do this with every feature. Higher numbers means the features should receive priority in the product development process.

Here’s a quick look at the house of quality’s ratings, what they mean, and how to use them:

Going back to the workplace communications tool, you may discover that certain integrations are more of a priority than others. The QFD shows that some integrations have a higher relationship with customer requirements.

After analyzing the results from phase one, move on to phase two, and so forth. Integrating the QFD into other phases ensures that the VOC is taken into consideration at every step of the product development process.

Now that you have a solid understanding of QFD, review these frequently asked questions before approaching your product team:

QFD stands for quality function deployment. It’s a structured framework to turn customer feedback into actionable technical requirements. Companies often use QFD to ensure the product matches customer expectations.

There are four phases of QFD, and they have a waterfall effect. This means you can’t complete phase two until you complete phase one. The results of phase one “fall” into phase two. The four phases are product planning, product development, process planning, and process quality control.

Six Sigma uses the quality function deployment (QFD) as part of its methodology. QFD provides a process to turn customer feedback into specific product requirements. By prioritizing customer needs, you can enhance product quality and customer satisfaction.

An example of QFD is a family-friendly vehicle. A product team gathers feedback from the targeted audience about what they want in their family’s vehicle. Customers may list features like safety, entertainment options, and automatic doors.

Organizing this information into a house of quality matrix can help identify which features should have priority in the car development process. The matrix compares features with technical requirements. The results show which features offer the most impact for customers and overall product success.

The purpose of QFD is to gather customer feedback and discover the product features that are most important to them. By prioritizing customer needs, organizations can ensure their efforts align with delivering value to customers.

There are several benefits of the house of quality. Some of the most important benefits include enhanced customer satisfaction, improved cross-functional collaboration, higher quality products, increased competitive edge, and efficient resource utilization.

Quality function deployment ensures the VOC is prioritized throughout the product development lifecycle. It positions customer needs and preferences as the driving force in creating a product suite that meets their expectations. QFD considers technical requirements and company resources in the development process.

Aligning customer needs with technical requirements is crucial to building a successful product. Many technical requirements interact with each other, and trying to change one may affect another one. The QFD makes sure that these interactions are accounted for when choosing which features to prioritize.

The structured approach of the house of quality matrix aligns the company’s potential with what the customer wants from your product suite. QFD also promotes the discovery of complementary features and can help discover unmet customer needs from your offerings.

You can use QFD to validate your product ideas, stay in touch with your customers, and confirm you’re on the right path to delivering products that satisfy your customers.

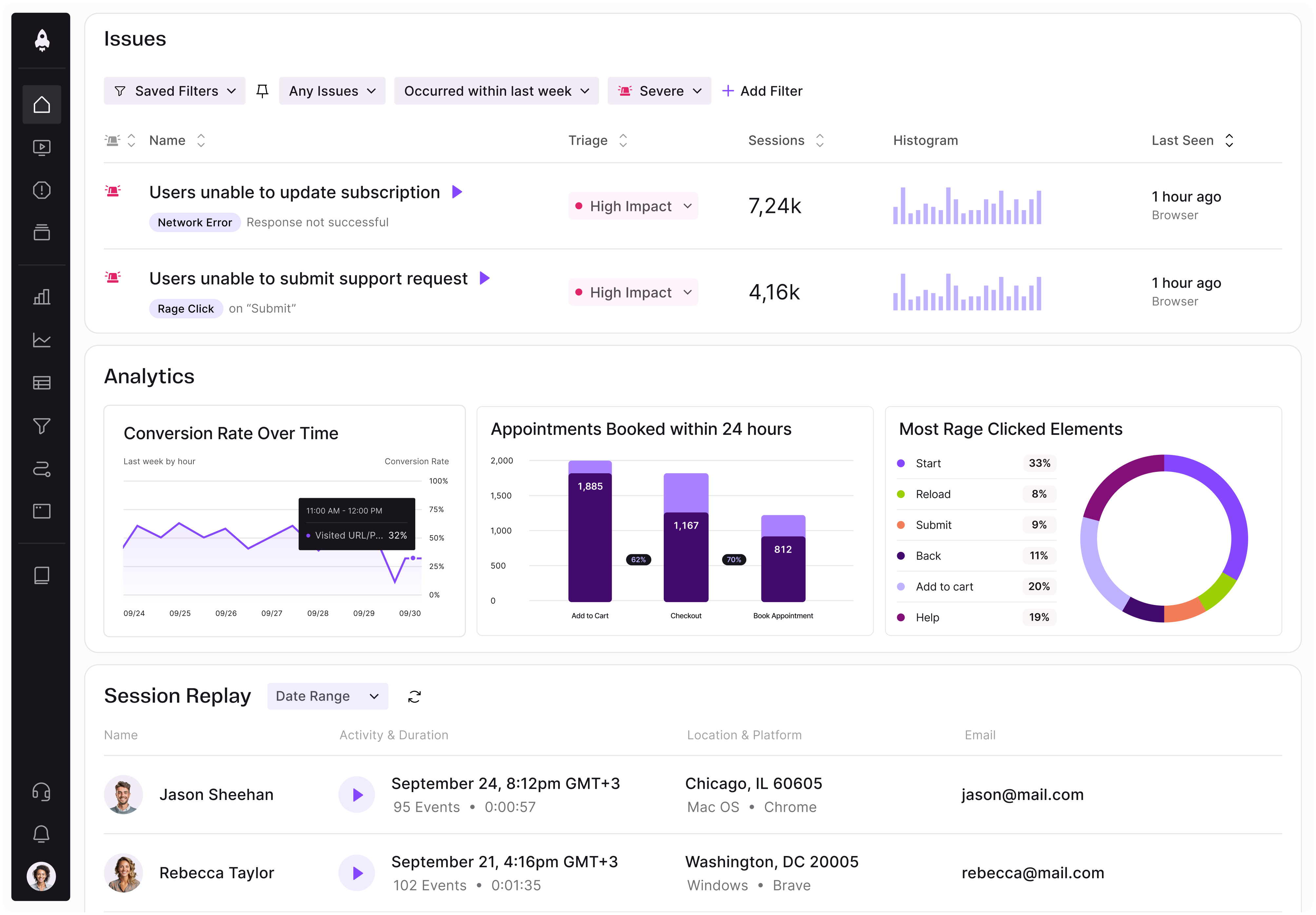

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

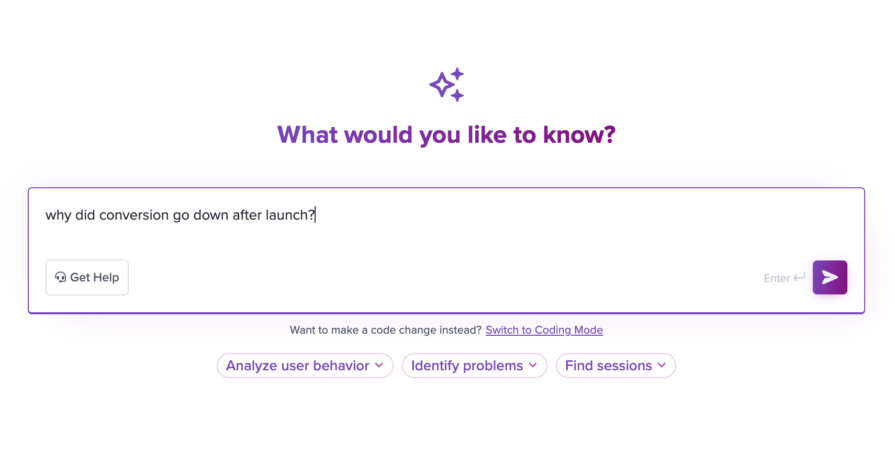

Introducing Ask Galileo: AI that answers any question about your users’ experience in seconds by unifying session replays, support tickets, and product data.

The rise of the product builder. Learn why modern PMs must prototype, test ideas, and ship faster using AI tools.

Rahul Chaudhari covers Amazon’s “customer backwards” approach and how he used it to unlock $500M of value via a homepage redesign.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.