Before delving into the practical and applied aspects of Little’s Law in the realm of technology and operations, let’s take a moment to indulge in some amusing anecdotes about this principle.

The law was named after its creator, John D.C. Little, but it’s widely believed that he gave it this name due to his small handwriting.

As for its real-world applications, particularly prominent in operations management for hotels, restaurants, and quick service restaurants (QSR), there is a humorous story. A Japanese restaurant that featured sushi served on conveyor belts introduced “Little’s Law fortune cookies” for its customers. This practice, common in Asian kitchens, involved predicting something whimsical for the day, such as “Today’s fortune: Your throughput rate will rise exponentially.”

Little’s Law holds immense power when applied in product and operational management. It is a valuable tool for enhancing efficiency and complements queuing theory in managing call centers, manufacturing lines, hospitals, restaurants, and service-oriented businesses. Ultimately, it empowers these establishments to better serve their customers by operating more effectively and efficiently.

In this article, we’ll explore Little’s Law and its wide applications in product and operation management.

Little’s Law is a theorem used to calculate the typical number of items or customers in a stationary queue system per unit time. According to the theorem, the average number of items (L) in the system is equal to the average number of items’ arrival rate (λ) multiplied by the average wait time (W) for an item in the system.

The law can be expressed algebraically as follows:

L = λ x W

Let’s understand this bit of complicated theory practically with a real-world example.

Imagine there is an offline clothes store that wants to optimize its checkout process on both normal and sale periods:

It also satisfies the condition that it is good if your store is functioning well daily without optimizing the checkout process. However, what if the average footfall, also known as arrival rate, increases 2x from 24 to 48 every hour during the sale season? Each customer takes around 40 minutes to find a dress, check out, and leave. Then approximately 28 customers are always in the store at a given time in line to check out.

This scenario indicates that an effective optimal number of checkout zones is required to minimize customer wait times in the queue. As customer arrivals increase, the efficient management of checkouts becomes crucial, as any misstep in this regard could result in frustrated and churned customers who dislike long waits.

Another important factor to consider by the retail store is that hiring one more cashier to optimize the checkout is a wise strategy or scaling up other available floor staff with accounting knowledge to cater to these seasonal situations. Hence, it takes the guesswork out of the equation, helping retailers make informed decisions to enhance customer satisfaction and ensure efficient service during peak times.

Therefore, Little’s Law helps businesses make decisions for efficient services to their customers.

Little’s Law is a helpful tool for enhancing business processes and streamlining operations by calculating the average number of items in a queuing system. It provides valuable insights into arrival rates and wait times, allowing informed decisions to be made regarding the resources required for a specific queuing system.

It is best to break down the queuing system into simpler variables to ensure efficient performance. By analyzing historical arrival rates and average system times, organizations can predict how changes in these variables will impact the number of items in the system. Little’s Law provides valuable metrics such as throughput, cycle time, and utilization which can compare and contrast the efficiency of different processes and systems.

Implementing Little’s Law correctly can significantly benefit your business operations and profitability. Furthermore, Little’s Law promotes continuous improvement, encouraging process owners to seek opportunities to enhance the system, experiment with new approaches, and drive innovation. This commitment to ongoing refinement ensures that critical process dimensions are continually monitored and adjusted, improving resource utilization and increasing productivity.

Little’s Law significantly benefits supply chain and fulfillment operations by reducing process lead time and increasing predictability. Customers always want their orders delivered as quickly as possible, and Little’s Law helps measure the delays in the order fulfillment process. Operations managers can use this information to reduce lead time and improve the predictability of order fulfillment.

In manufacturing operations, managing multiple processes can increase working capital. Little’s Law helps reduce process lead time, improving productivity, and reducing work in progress. This, in turn, positively impacts key performance indicators such as productivity, faster turnaround time, increased capacity, and efficiency.

Product management can benefit greatly from Little’s Law. Its applications, ranging from driving programs to managing kanban boards and agile methodologies, can simplify processes and improve efficiency.

Here are some usages of Little’s Law in software development and product management:

A straightforward application of Little’s Law is in managing projects. It is often used to effectively manage various aspects of project execution, including release cycle time, resource allocation, and capacity planning.

Program managers use Little’s Law to estimate release times by considering key factors such as the average number of projects in progress (L), the rate at which new projects are initiated, and the average time required to complete each project (W).

The practical implementation of Little’s Law also extends to software testing. It plays a pivotal role in optimizing the size of the test cases queue to ensure efficient test execution.

By leveraging Little’s Law, teams can determine the ideal queue size, enabling them to allocate the appropriate number of testers and other resources effectively. This data-driven approach enhances software testing efficiency and, consequently, contributes to the overall success of the process.

Little’s Law, a concept typically associated with physical processes, isn’t commonly applied to knowledge-based work like software development. This may be because it’s more challenging to visualize and quantify intangible processes.

However, this is precisely where kanban systems come into play, offering a powerful solution. Incorporating a software development process into a kanban system allows teams to represent their work using visual elements like kanban cards.

Work in progress (WIP) in software development can encompass various items, such as user stories, bugs, feature requests, and more, all flowing through the kanban system as represented by these cards. Teams can then measure their WIP, throughput, and lead time over specific periods.

For example, if your kanban board has an average arrival rate (λ) of five user stories per week, and it takes two weeks to complete a story (W), then on average, you will have 5 x 2 = 10 user stories in WIP on the kanban board.

Little’s Law can be a valuable tool for managing your agile team’s WIP limits. If you aim to keep the average number of user stories (L) in progress at 30, and your arrival rate (λ) is 10 stories per week, you can establish a sprint WIP limit of three stories per week.

Furthermore, Little’s Law finds practical application in estimating release completion times. With a firm grasp of your arrival rate (λ) and the desired backlog size (L), you can accurately determine the lead time (W) necessary to clear the backlog.

By applying Little’s Law in an agile context, a product manager can deepen their understanding of the intricate dynamics involving arrival rate, lead time, and work in progress. With this understanding, one can make well-informed decisions, optimize agile processes, boost team performance, and effectively achieve release goals.

I’ve shared several examples of Little’s Law in action, like a retail shop and software development. In this section, I want to revisit a very popular example from healthcare operation management, one that is often discussed in operation management classrooms and remains highly relevant today.

First, we’ll look at how to apply Little’s Law in healthcare to determine how long patients stay in the hospital. This involves considering disease states, phases, and surgical procedures. We have some data points to help us with this:

Using Little’s Law, we can calculate the average waiting time for a patient in the queue, which tells us how long they can expect to stay in the hospital. The formula is:

W = L / λ

In simpler terms, the average time spent in a hospital equals the average number of patients divided by the average discharge rate. By plugging in the numbers, we can calculate as follows:

Average time in hospital = 240 patients / 100 patients per day = 2.4 days

This information is invaluable for hospital administrators, guiding them toward improved care, staffing, budgeting, and ultimately a higher quality of service for their patients.

Little’s Law is an effective tool for understanding and managing systems with queues and waiting times. Its straightforward formula is invaluable for enhancing the efficiency of various systems in domains such as operations management, logistics, service delivery, and software development. However, it’s important to recognize its prerequisites and limitations to ensure the accuracy and relevance of the insights it provides.

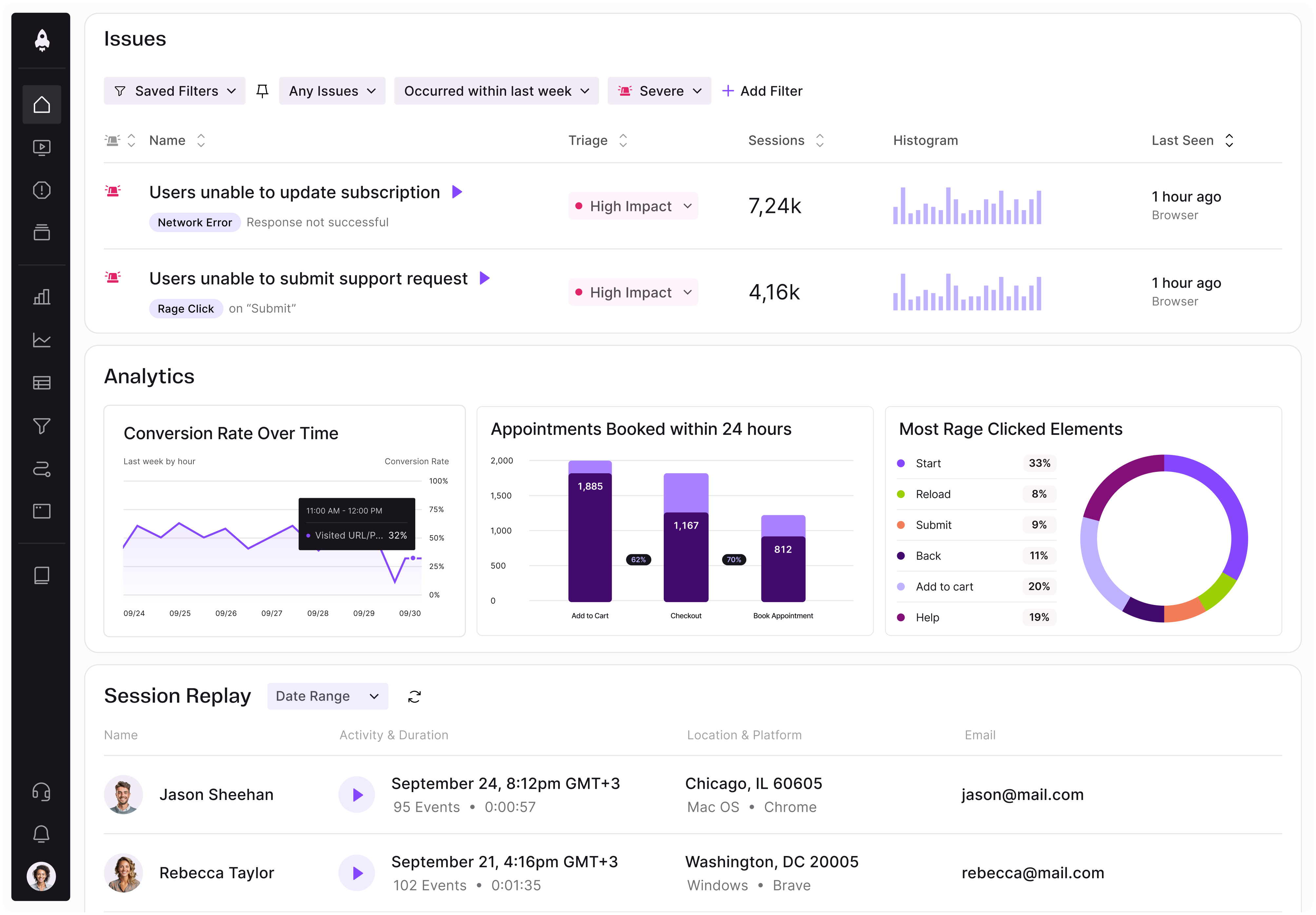

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

Rahul Chaudhari covers Amazon’s “customer backwards” approach and how he used it to unlock $500M of value via a homepage redesign.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.

Maryam Ashoori, VP of Product and Engineering at IBM’s Watsonx platform, talks about the messy reality of enterprise AI deployment.

A product manager’s guide to deciding when automation is enough, when AI adds value, and how to make the tradeoffs intentionally.