Part of staying profitable is ensuring that your processes run smoothly and at maximum efficiency. However, you may find yourself in a situation where stakeholders have different understandings of a business process. The confusion can lead to missed opportunities for process improvement.

Using SIPOC (suppliers, inputs, processes, outputs, and customers) can help you create a visual diagram of your business processes while also identifying areas of improvement.

In this article, you will learn what SIPOC is, its benefits, and how you can use it within your product team.

SIPOC is a visual tool to document a specific business process and look for process improvements. The diagram reveals the inputs and outputs of the process in a table form.

You can use SIPOC diagrams to help stakeholders familiarize themselves with the key elements of a process. You may also use SIPOC to help focus discussions or bring together a team.

SIPOC is part of the Six Sigma process improvement methodology. It is often used during the define phase of the DMAIC methodology. SIPOC is also part of lean manufacturing and business process management principles.

Occasionally businesses will use an alternative called COPIS to create their business process diagram. It’s essentially the same principles but with a focus on customers.

SIPOC is an acronym for each column of the diagram. Let’s discuss each column and what follows under that category:

When each column is filled out, it will create the SIPOC diagram.

SIPOC gathers key information about a business process and puts it into one diagram. By completing a SIPOC diagram, a product manager can learn the following:

Knowing these elements helps with the overall process improvement. A finished SIPOC diagram can reveal flaws in the process, aid in conducting process analysis, and can easily show stakeholders what is happening. It’s also useful for ensuring teams have a centralized location for understanding the process.

You may want to use a SIPOC for evaluations like:

SIPOC is a type of process map. However, it differs in the scope of detail. Unlike other types of process maps which hone in on every detail of a process, a SIPOC diagram is a simple high-level overview of the process. It also includes a look into customers and suppliers to further visualize process relationships.

You can gain several benefits by using a SIPOC diagram, especially if you implement the Six Sigma methodology. SIPOC:

Let’s say that you wanted to make a SIPOC diagram of a business process like hiring new employees. The process to find a new employee in a SIPOC diagram may look a little like this:

| Suppliers | Inputs | Process | Outputs | Customers |

|---|---|---|---|---|

| Job boards, staffing agencies, referrals |

Job description, resumes, assessments |

Screening interviews, background checks, hiring decision |

Job offer, onboarding, paperwork, employment contract |

New employee, hiring manager, HR department |

By using this SIPOC diagram, you can discover missed opportunities. For example, it could have used social media to share news it was hiring. You can also be prepared to share the process with the hiring manager and ensure they are informed on how to hire a new employee.

The SIPOC template is easy to use, but it can take some time to accurately complete. You’ll need a full understanding of the entire process from beginning to end and who is involved. While you can complete this by yourself, you’ll eventually need to share it with your team to validate it.

Before going into the step-by-step instructions on how to make a SIPOC diagram, here are a couple of tips:

Let’s dive into how to create your SIPOC diagram:

SIPOC diagrams work best when a specific stream or process is chosen to evaluate. You’ll want to choose a process that will benefit from being charted into a SIPOC diagram. Defining the process you want to evaluate will help your team ensure all the necessary information is collected.

The second step is to fill out the process column of the diagram. You’ll want to identify the sequence of events that will lead to your outputs. Since this is a high-level diagram, don’t get bogged down with every little detail. A good rule of thumb is to keep it under seven steps. Otherwise, it will become hard to follow and defeat the purpose of a SIPOC diagram.

Identify the outputs of the process. This could be a product, service, or information. To keep it simple, only use nouns to describe the outputs. There should be little to no supporting information on the outputs. This step helps show what customers are actually receiving after a process is completed.

Despite the name, the customers column doesn’t always mean people purchasing from your organization. It could also be team members benefiting from a certain business process. The customers column is anyone who receives the outputs of a process. It could also describe the target audience of the outputs or who will want it.

The inputs are everything that needs to be successfully implemented for the process to work. You’ll need to identify raw materials, software, or other resources in the inputs column. Remember that we’re aiming to create a high-level diagram, so it’s not necessary to put every input. Instead, focus on including the essential, overarching inputs.

The final step in creating the SIPOC diagram is to identify the suppliers. You’ll want to list suppliers that contribute resources necessary for the inputs. For example, if you want to make a dress, a supplier may include fabric shops.

Once you have created a SIPOC diagram, it’s time to validate it with your team. Share it with relevant stakeholders and make any necessary changes. You may discover you’ve missed some crucial points. Once the SIPOC diagram is accurate, you’ll have a centralized document for how a process works.

After creating a SIPOC diagram, your team can review all the processes and identify opportunities for improvement. Then your team can create an action plan to improve the current business processes.

The SIPOC exercise is a great tool for documenting processes and ensuring they are running as efficiently as possible. It should be part of your overall toolkit for process improvement, especially if you use Six Sigma and DMAIC methodology in your organization.

Featured image source: IconScout

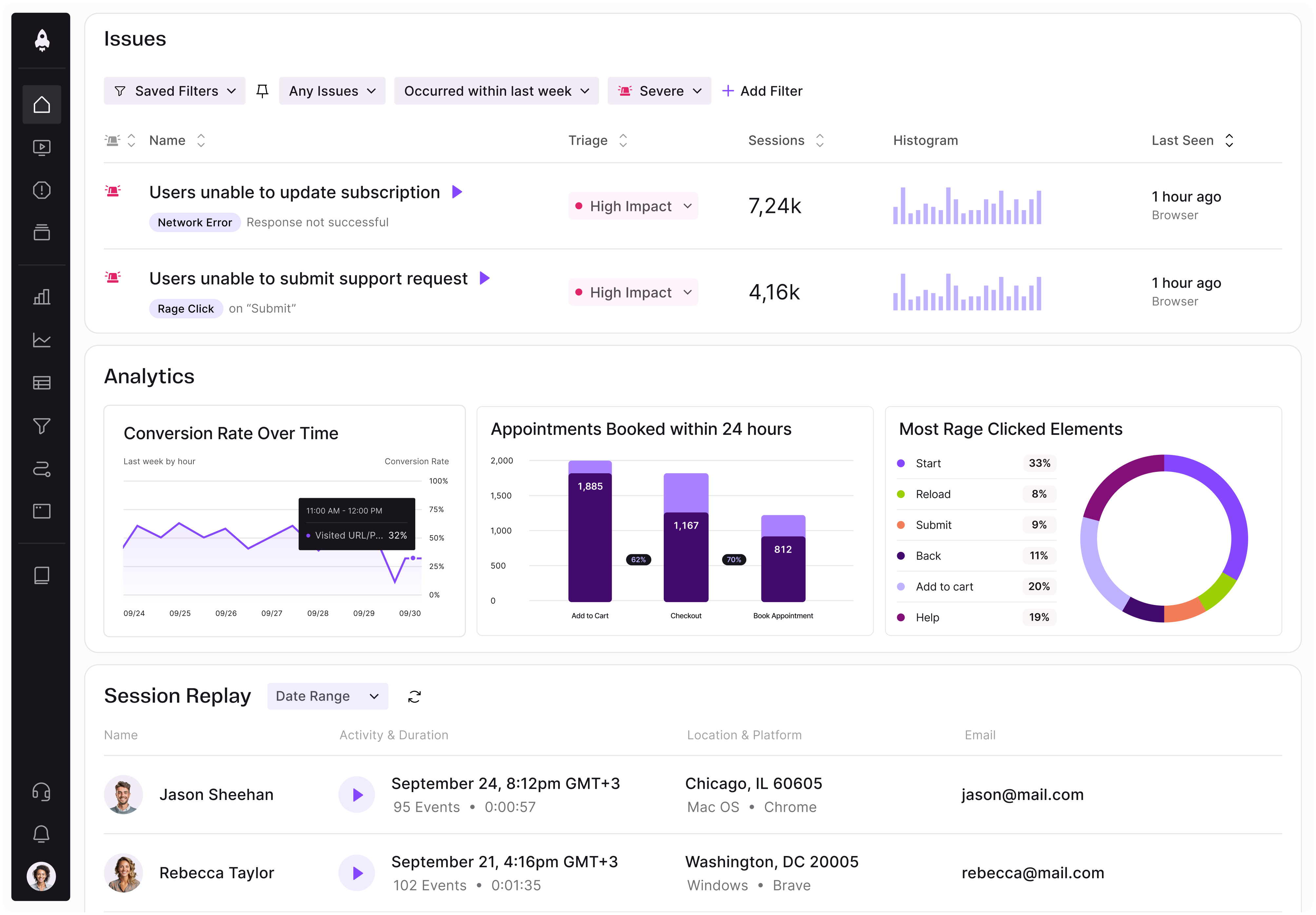

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

Rahul Chaudhari covers Amazon’s “customer backwards” approach and how he used it to unlock $500M of value via a homepage redesign.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.

Maryam Ashoori, VP of Product and Engineering at IBM’s Watsonx platform, talks about the messy reality of enterprise AI deployment.

A product manager’s guide to deciding when automation is enough, when AI adds value, and how to make the tradeoffs intentionally.