Improving business operations can be a wide-ranging and daunting task. One method organizations use to enhance performance and efficiency is known as the fit gap analysis. This analytical method offers a precise lens through which companies can scrutinize their current performance and compare it with their potential.

A fit gap analysis can help you shed light on discrepancies hindering optimal performance, create streamlined strategies, and accelerate toward your business objectives. But how do you conduct a fit gap analysis? What are the challenges that might surface, and how can these obstacles be navigated?

In this guide, we’ll help you unlock the secret to amplifying business success using the fit gap analysis approach.

A fit gap analysis is a detailed assessment of how a current or proposed solution aligns with the organization’s business processes, operations, and overarching goals. This method usually involves assessing a current or planned system, but occasionally it may also be applied to business processes or standard operating procedures.

The result of a fit gap analysis is a list of “gaps” that illustrate where the current or proposed solution falls short in meeting the operational needs of the business.

The typical steps involved in performing a fit gap analysis are as follows:

The first step is to examine your current business processes. To do this, you’ll need a solid understanding of all the tasks and steps involved in your operations.

You can gain this understanding through a mix of employee interviews, process walkthroughs, and a review of existing process documentation. The goal is to map out the process as it exists currently, complete with steps, roles, inputs, outputs, and any decision points.

After you’ve assessed your current process, you’ll need to evaluate the results of that process. This involves examining both quantitative metrics, such as throughput, error rates, and cycle time, and qualitative outcomes, such as customer satisfaction and employee morale.

It’s important to evaluate these results in light of your organization’s strategic goals because the fit gap analysis seeks to align processes with these objectives.

The next step involves defining what you want the process to achieve.

Again, these desired results should be grounded in your organization’s strategic goals. They may include improving customer satisfaction, reducing error rates, or increasing process speed.

You should express these expected results in measurable terms, using specific metrics that will allow you to assess the success of process improvements.

Now that you’ve evaluated your current process and defined what you want to achieve, it’s time to determine the gap between the two. This involves identifying the differences between your current process and the desired future state.

Document these gaps in a structured way that highlights the specific areas of the process that need improvement.

With the gaps identified, you’ll need to determine what needs to change to bridge these gaps. This may involve modifying steps in the process, changing roles or responsibilities, introducing new technology, or redefining performance metrics.

Each of these changes should be clearly linked to a specific gap, providing a roadmap for process improvement.

Finally, you may need to develop new applications or systems to support the redesigned process. This could involve the use of artificial intelligence (AI) technologies or other software solutions to automate certain tasks, enhance decision-making capabilities, and improve process visibility.

A fit gap analysis can be conducted using several methodologies, each focusing on a different area, such as processes, systems, or resources.

In the following sections, we’ll delve into specific types of gap analysis, provide templates for each, and discuss when it’s most appropriate to use each method.

A process gap analysis is designed to help reveal gaps in your organization’s processes. This process gap analysis template helps visualize and track these gaps, taking into account their criticality, category, origin, and additional notes for each identified gap:

| Process area | Category | Criticality | Source of gap | Gap details | Proposed process changes |

| Process 1 | Workflow | High | Inefficient process steps | Time-consuming manual data entry leading to errors | Implement automation for data entry, reducing errors and improving efficiency |

| Process 2 | Lead time | Medium | Lack of performance metrics | No tracking system in place to monitor lead times | Introduce performance tracking software to monitor and reduce lead times |

Note that the template is populated with example data; you should replace that data with information specific to your project or business, and add rows as needed.

Consider this template when your business processes are inefficient or not generating the desired outcomes. Process-based gap analysis is strongly recommended when the inefficiencies can be traced back to the design of the processes themselves, rather than the systems that support them.

For instance, workflows may be missing or siloed, and handover touchpoints may need better definition. Following a process gap analysis and the resulting process transformation, a review of the supporting systems would likely be necessary.

A system gap analysis is intended to identify gaps within your organization’s systems, examining aspects such as system category, the reason for the gap, additional information on the system gap, and required updates to align the system with business needs.

Use the template below as a starting point for your system gap analysis:

| System | Type of system | Number of users | Source of gap | Gap details | Proposed system updates |

| System 1 | IT system | High | Issues with third-party integration | Integrations are frequently breaking down causing downtime | Upgrade to a more reliable integration system or partner with a more stable third-party |

| System 2 | Business process tool | Medium | Outdated or heavily manual processes | System requires manual intervention causing delay in processes | Update system to include automation capabilities for reducing manual intervention |

Note that the template is populated with example data; you should replace that data with information specific to your project or business, and add rows as needed.

The system gap analysis template is most useful when the systems within your organization are not fostering efficiency or productivity. This might suggest that while business processes are well-defined, the systems in place to support them are not as effective as they could be.

Whether it’s due to poor third-party integrations or outdated technology, a system transformation may be in order. This template can facilitate that transformation by clearly outlining the current system gaps.

A resource gap analysis, unlike the process or system gap analysis, is inherently forward-looking. It’s designed to identify what resources will be needed to carry out future projects or programs, comparing that with the resources currently available within the organization.

Here’s a good template for a resource gap analysis:

| Resource pool or type | Resource category | Importance of resource group | Source of gap | Gap details | Updated resource requirements |

| Resource pool 1 | Business | Low | Unqualified candidates | Several applicants lack necessary skills or qualifications | Revise hiring strategy to focus on more specific qualifications |

| Resource pool 2 | HR | Medium | Insufficient number of candidates | Current resource pool unable to meet increasing HR needs | Launch recruitment drive to attract more qualified candidates |

Note that the template is populated with example data; you should replace that data with information specific to your project or business, and add rows as needed.

A resource gap analysis is particularly useful when current resources are insufficient to meet the needs of future projects. It’s applicable in scenarios where the organization’s systems and processes are aligned with business needs or have been updated based on previous gap analyses, but the manpower or resources are inadequate.

Actions following this analysis may include hiring, reskilling, or cross-training to better equip your team for future challenges.

When conducting a fit gap analysis, it’s common to encounter several challenges along the way regarding things like:

A fit gap analysis can be an incredibly effective tool for identifying areas of continuous improvement and alignment with expected business outcomes. It can be even more impactful if you keep a few best practices in mind while you’re performing fit gap analyses:

Fit gap analysis is an essential tool to optimize any organization and ensure the processes are working according to business goals. While this process comes with its own challenges, it is instrumental in assessing and performing the corrective steps to keep the organization aligned.

The analysis helps derive solutions to resolve the gaps and offers guidance on how to prioritize these solutions for implementation. As such, a fit gap analysis serves as a powerful mechanism for performing a status check, making corrections, and improving the overall efficiency of an organization.

Featured image source: IconScout

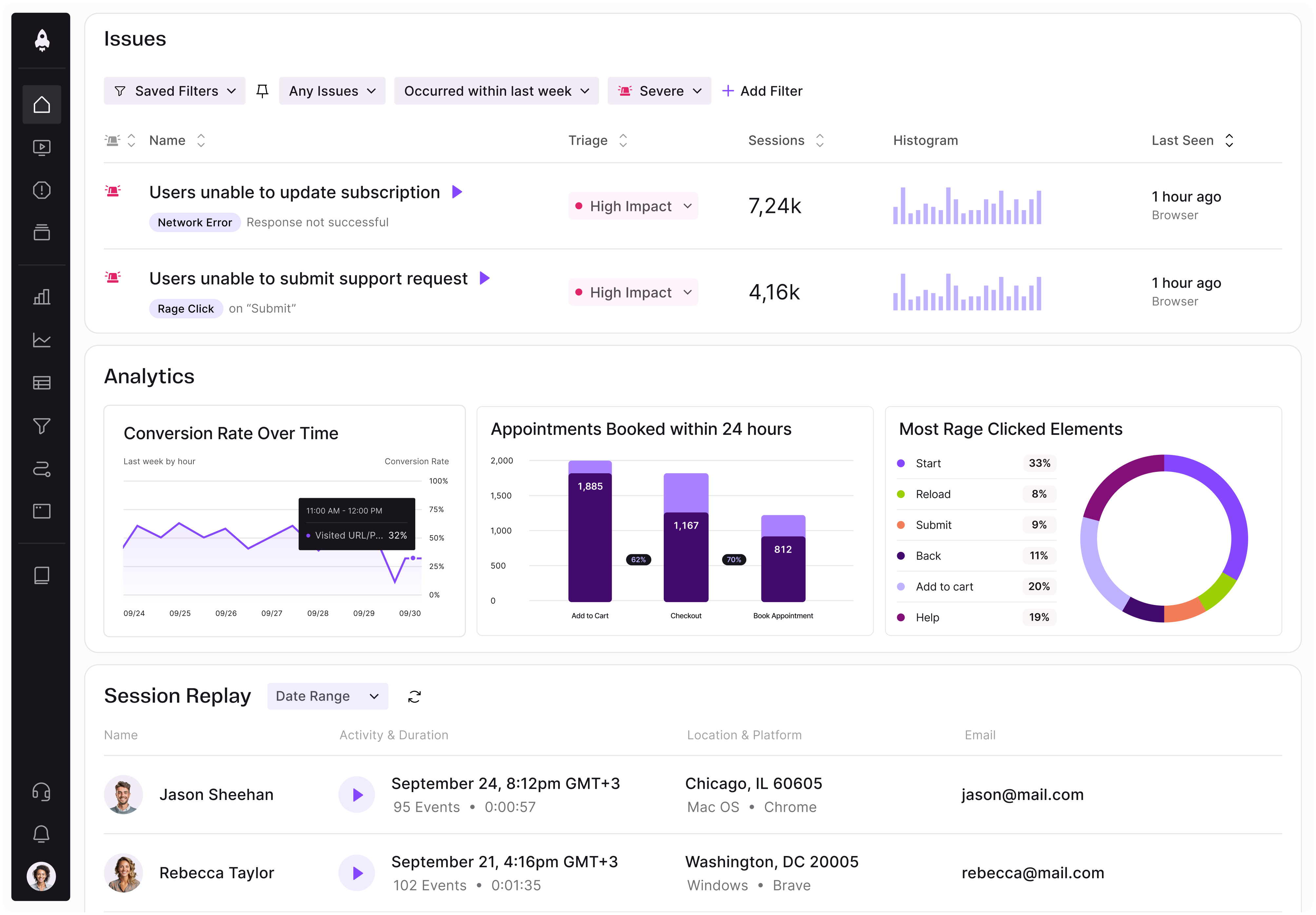

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.

Maryam Ashoori, VP of Product and Engineering at IBM’s Watsonx platform, talks about the messy reality of enterprise AI deployment.

A product manager’s guide to deciding when automation is enough, when AI adds value, and how to make the tradeoffs intentionally.

How AI reshaped product management in 2025 and what PMs must rethink in 2026 to stay effective in a rapidly changing product landscape.