Efficiency is the key to running a successful business. How do we measure efficiency? Higher value to customers, more revenue, reduced operational costs, and fine-tuned processes, to name a few.

Of course, the success criteria depends on the company, the products it develops, and the processes it implements.

Understanding the kind of product being created is key to making decisions that improve the overall efficiency of the company. A popular tool to help with this is the product process matrix (PPM).

The product process matrix was first introduced by Robert Hayes and Steven Wheelwright in their book, Restoring Our Competitive Edge: Competing Through Manufacturing, published in 1984. It is a framework used to visually represent the relationship between product development and the production process lifecycle, progressing towards a more cost-effective and standardized product structure.

The product process matrix helps us understand the optimal production process based on the volume of items produced and the customization required. In manufacturing systems, products usually vary in their type and complexity.

The matrix puts into perspective the type of product that is being produced, the volume at which the product is being produced, and how it is being produced.

The product process matrix can be a useful tool for PMs to analyze and identify the best production approach for the products they are building.

You can also use it as a framework to estimate your company’s competitive advantage and unique standing in the market, both in terms of the product you’re offering and the process you implement to produce it.

The product process matrix provides insights into the operations of producing the product at scale, identifying the root causes of bottlenecks and issues, resolving them, and making processes very efficient.

As a product manager, you can also use the product process matrix to educate management, the development team, cross-functional teams, and other relevant stakeholders on the product-process lifecycle.

When processes are standardized and, better yet, automated, it helps provide a consistent, high-quality product. When this is done at scale, it significantly reduces the development costs and increases the company’s profitability. Furthermore, understanding the product process matrix helps product managers make informed decisions on resource allocation, product strategy, and overall product development.

While the product process matrix was initially developed to address manufacturing processes, its principles can also be applied to software product management.

The key is to adapt the framework to the unique nature of software development, considering factors such as the level of customization, the target market, and the software development methodology being used. Here’s how software product managers can leverage the product process matrix:

As you can see, while the product process matrix was originally developed for manufacturing, it can also provide valuable insights and guidance for software product managers. By adapting the framework to the unique context of software development, product managers can make more informed decisions, optimize their development processes, and ultimately deliver better products to their customers.

In manufacturing, the PPM helps to identify the most efficient production process for a product based on its type and complexity, as well as the volume at which it is being produced. In software development, it can help PMs determine the most appropriate production process for their software based on factors such as volume of items produced and customization required.

The product process matrix helps PMs streamline the activities required to produce the software at scale, resolve bottlenecks and issues, and make product operations more efficient in general. Additionally, the it enables them to respond strategically to industry and market shifts by identifying areas where the production process could improve.

Understanding which type(s) of production process(es) your digital product falls under can help you make informed decisions about how best to allocate resources, design workflows and improve efficiency in your product development lifecycle.

The five types of production processes are:

Job shop production is characterized by a high degree of customization and low volume. In software development, this might apply to projects that require significant customization and are unique to each customer or user.

For example, say you have a software product that is designed to be adaptable to users’ unique needs. In this case, you would want to implement a production process that allows for flexibility and customization, even if it means higher costs per unit produced.

The batch production process involves moderate customization and moderate volume. Digital product managers might take a batch production approach to projects that have some level of customization but still share many common features.

Let’s say you’re producing a content management system that is used by multiple clients, each with their own unique branding and customization requirements. The production process for this product would involve creating a set of core features that are shared across all clients and then customizing them to meet each client’s specific needs.

The batch production approach allows for efficient use of resources while still meeting the customization needs of individual clients.

Assembly line production allows for low customization and high volume. This approach is suitable for digital products with minimal customization requirements but that are used by a large number of users.

For example, imagine you’re developing a mobile app that has a standard set of features but requires minimal customization for each user. You would want to develop a standardized process for building and releasing the app, with each release being identical in terms of its core features but with minor variations to accommodate user preferences or device specifications.

By using an assembly line approach, you can ensure consistency and efficiency in your development process while still providing some degree of customization for users.

This type of production process is characterized by minimal customization and very high volume. In software development, this could apply to products such as mobile apps or web platforms that require little customization but are used by millions of people.

For instance, a social media platform like Facebook or Twitter would benefit from a continuous production process because they need to handle large amounts of data quickly and efficiently. The development team can optimize their processes for speed and scalability, resulting in a consistent product experience for millions of users.

By adopting a continuous production process, the development team can also reduce costs associated with maintaining the software while ensuring it remains stable and reliable.

FMS refers to a highly automated system that can produce multiple products with varying levels of customization. You might consider applying an FMS approach to a suite of products or applications that share common features but also have unique customizations for different customers or users.

An example of using FMS production in software development is a project management tool that can be customized according to the needs of the organization. The core features remain the same, but additional modules and functionalities are added based on the client’s requirements.

This also falls under the batch category in the product process matrix because it involves moderate customization and volume. By using an FMS approach, the development team can efficiently produce multiple versions of the product while still maintaining a high level of customization for each client.

Product managers often use the product process matrix to determine the most appropriate production process for their products. By evaluating you product’s degree of customization and production volume, you can identify the production process that best aligns with their goals and requirements.

For example, if you’re overseeing the production of a highly customized, low-volume product, a job shop production process may be the best fit. On the other hand, if you’re responsible for producing a high-volume, standardized product, an assembly line or continuous process may be more appropriate.

It is also important to note that a company’s position in the product process matrix can change over time as its products evolve and production processes improve. It’s a good practice to regularly review and adjust your production strategies to ensure that your company remains competitive and responsive to changing market demands.

Here are some ways you can apply the framework in digital product management:

When designing new products, you often have to think about how you would produce the product, how you would go to market with it, and what your pricing strategy would be.

The product process matrix provides the framework you need to make these decisions. It also helps you formulate your sales and marketing strategy by helping you identify the right product-market fit and the positioning/messaging that’s appropriate for it.

Use the framework to identify where your product fits and then make the decisions that pertain to its placement in the framework.

After you release a product in the market, you can gauge customers’ response and gather product feedback. Some insights might lead you to create different variants of your products.

For example, if you were producing a body wash with aloe vera, you might find that you have a significant user base that would like a nice scent added to it and others that don’t like the aloe vera all that much. By using the product process matrix, you can identify what the product variants should be and how they should be produced.

You can’t always oversee the entire production process. For example, you might need to source raw materials or services from a partner or vendor.

You can, however, leverage the product process matrix to understand the production capabilities of your partners and vendors to ensure that they have the experience you need. The PPM can also help you improve communication with these vendors because all parties understand where the product lies within the framework.

As you map out the product lifecycle and understand the production process better using the product process matrix, you can also identify process issues and opportunities for improvements.

Understanding the level of product customization helps you reduce waste, lower costs, improve efficiencies, and optimize production process. This insight also helps you improve communication and collaboration across the team and align processes with the product vision.

The product process matrix can be leveraged to manage the product lifecycle from conception to development to retirement.

Keep in mind that the most appropriate production process might change as the product moves through the development lifecycle. For example, during the development stage, a job shop may be the most appropriate production process, while during the growth stage, a batch process may be the most appropriate.

Leverage the product process matrix in your day-to-day product activities and over time to help improve your product lifecycle. The sooner you know where your product sits within the framework, the closer you are to finding your product-market fit.

Keep the matrix up-to-date in tune with these changes and communicate the updates to team members in a timely manner. Document these updates for better collaboration and alignment.

Leveraging the product process matrix is, of course, very helpful to product managers. But the framework becomes useless if it remains static over time and relevant information doesn’t get distributed.

Here are some best practices for using the product process matrix:

Educate your team members

Help your team members understand what PPM stands for and how it can help improve the product and the production process.

As a product manager, you need the support of your team members. When they understand why and how to use the framework, it will help align the team toward shared business goals.

Collaborate with cross-functional teams

Use the matrix to identify the appropriate production process and use it as a guide to communicate the production process with cross-functional teams.

The more you’re able to communicate with other team members, the better the collaboration across teams. This will help improve the overall quality of the product.

Keep the matrix up-to-date

Over time, things change — from product requirements, to business priorities, to strategic goals.

As any agile product manager knows, you must embrace change to keep up with changing market trends. It’s important to keep the matrix up-to-dateand communicate any updates to team members in a timely manner. Document these updates for better collaboration and alignment.

Regularly review and refine your matrix

Sometimes, it can be hard to understand the nature of the product right off the bat and predict customer response. Market trends might not change significantly, but product needs might change over the product lifecycle.

To mitigate risks early, regularly review and refine your matrix. Again, document and communicate any updates you make.

Stay ahead of market trends and competition

Market trends and competition can sometimes throw a wrench into your product development process.

For example, if global supply of an important raw material was suddenly limited but your competition already acquired massive volumes of that raw material, it can put you at a serious disadvantage.

It’s important to monitor the market and your competitors to understand the risks involved and how you can mitigate them.

Remember that the product process matrix is a continuously evolving document. Involve other team members to help you keep the matrix up-to-date and communicate the changes with others. Doing things by yourself can be quite overwhelming, but when you make it a team effort, it gets much easier.

While the product process matrix can be a valuable tool for product managers, it is not without limitations. Some criticisms and potential drawbacks include:

Follow these five steps to build your product process matrix:

The first steps is to determine the degree of customization required for your product. Next, consider the volume at which the product needs to be produced. These are the two most critical characteristics to nail down before considering the most suitable production method.

At this stage, you need to think a few steps ahead and consider how you would want to scale your product and, additionally, how you want to go to market with it. These considerations should lead you to choose the most suitable production process for your product from the five types listed above.

First, map the x-axis with your product structure in terms of volume and customization

Next, map the y-axis with your process structure in terms of the four process components: jumbled flow, disconnected line flow, connected line flow, and continuous flow.

Finally, map your product within this framework to identify the appropriate production process for your product.

Here’s a simple product process matrix template you can follow to help you get started.

Outline each step in your production process from start to finish. It’s also critical to understand the sequence of actions required as well as any dependencies that might need to be included.

Once the production process is complete, gather feedback from relevant stakeholders and adjust the matrix as needed. Keep track of any changes to the process and document why those changes are being made.

The matrix will necessarily evolve over time as environmental factors change.

Still not sure where to start? You can use this free product process matrix template to help you carry out the steps outlined above.

To user the template for your own production process, choose File > Make a copy from the main menu above the spreadsheet.

The product process matrix is a valuable tool for product managers looking to understand the relationship between product customization and production processes. By identifying the appropriate production process for a given product, you can optimize product operations and better support customer needs.

However, it is important to recognize the limitations of the matrix and consider other factors that may impact production strategies. By staying flexible and adaptive, you can ensure your business remain competitive in an ever-changing marketplace.

Featured image source: IconScout

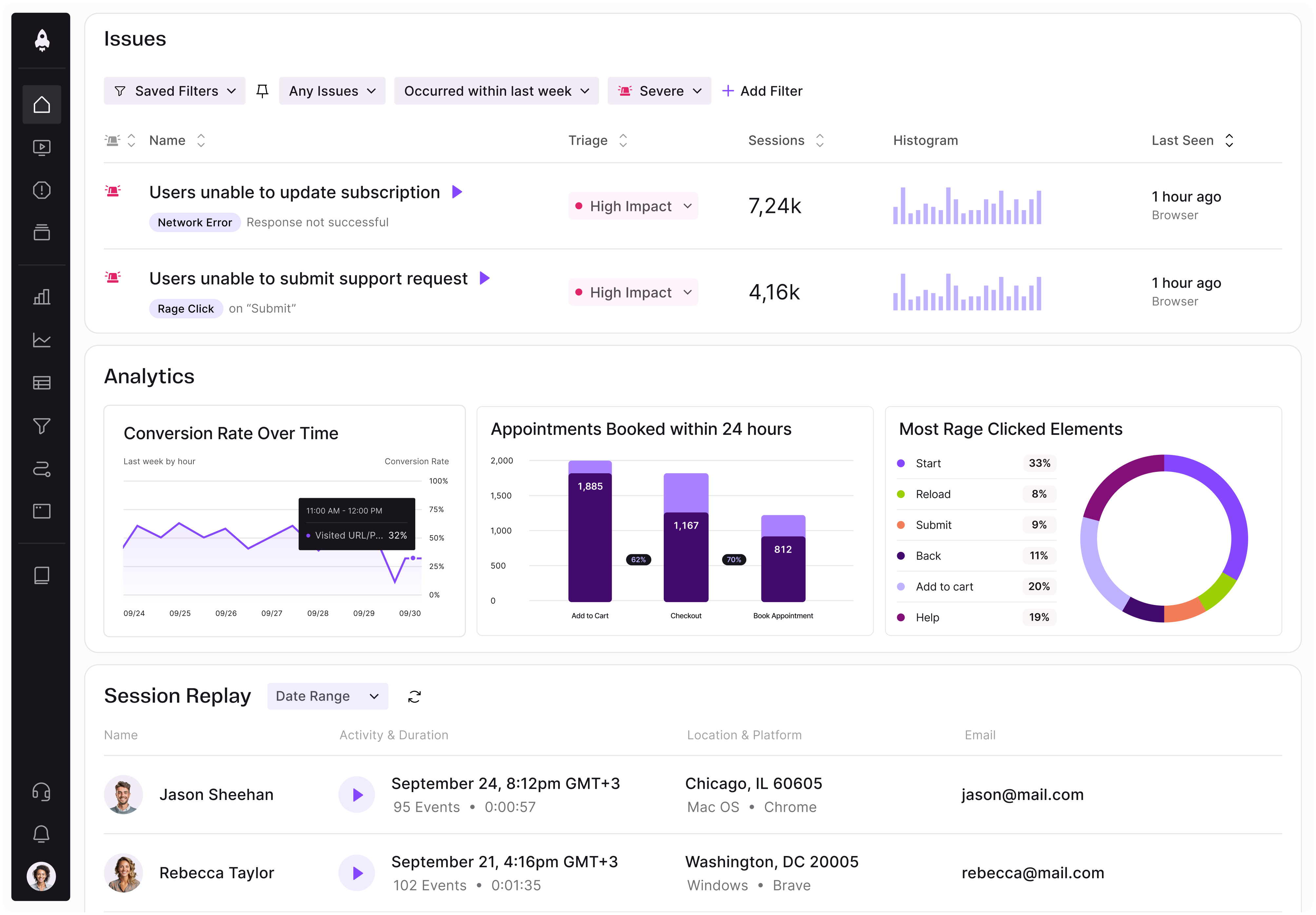

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

Rahul Chaudhari covers Amazon’s “customer backwards” approach and how he used it to unlock $500M of value via a homepage redesign.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.

Maryam Ashoori, VP of Product and Engineering at IBM’s Watsonx platform, talks about the messy reality of enterprise AI deployment.

A product manager’s guide to deciding when automation is enough, when AI adds value, and how to make the tradeoffs intentionally.