There’s a famous saying in product management: if you’re not changing, you’re stagnating. And if you are standing still, your competition will outmaneuver you.

Makes sense, doesn’t it? In that case, why do we see many organizations doing the same thing they have always done?

In this article, we will first explore the dilemma of standing still while change is happening all around us. Then, we will dive into eight ways to embrace continuous process improvement.

Process improvement involves an investigation of each stage of your product development to ensure maximum efficiency and effectiveness. You can think of this as optimizing the product process to deliver the most value to users. In order to successfully improve your process, you have to have an open mind and encourage innovation among your team members.

It’s easy to get comfortable with the familiar.

Most people know that to compete, you must change to meet evolving conditions. But, still, you might find yourself struggling to break free from your current way of working.

Why is this?

It comes down to eight primary reasons:

Let’s face it, changing requires giving up what’s comfortable and familiar for the unknown. It’s a risk. But continuing to do the same thing is also a risk.

Consider whether the reward of changing might be greater than the risk of staying the same. This will help you avoid stagnation.

The longer inspection and adaptation are avoided, the harder it is to change. When reflection only comes at the end, you can run out of time to adapt.

Think of all the practices that inspect after the work is finished. To name a few, consider retrospectives, postmortems, and yearly reviews. These usually happen too late in your process for you to make meaningful changes.

All the inspection and reflection in the world doesn’t matter without the space to adjust course. Yet, you might find that you get so busy following a plan that you don’t budget time to change.

You might fear that spending the time to pivot will take longer. The shortest path is rarely a straight line, as learning doesn’t result in a linear path.

If you put boundaries around change, you restrict your practice of a new behavior.

One typical boundary put on change is making it periodic. You have weekly innovation days or infrequent innovation events. Then, when these events end, you go back to our existing habits.

If you practice changing periodically, the rest of the time you are practicing our status quo. To change your patterns, you first have to stop the existing behavior. Then, you need to practice the new behavior repeatedly and often.

Typically, product managers meticulously plan out a change. Then, you roll out the homogeneous change all at once. This is a closed, top-down approach that inflicts change and ignores co-creation.

Without buy-in, a change is doomed to fail.

Many hold out false hope that what worked for them in the past will continue to work. They then miss out on opportunities to improve.

This belief will lead you to a state of wishful thinking. You might find yourself holding onto existing behaviors past their expiration date.

Many organizations have departments for different functions. Change is no different. Change departments and functions are widespread.

Modifying behavior is difficult. This is one reason why many choose to centralize it to a group of specialists. But centralization ignores a key aspect: change is situation-dependent. It is not amenable to cookie-cutter rollouts.

Change groups are too far removed from the situation on the ground. They lack context and their decision-making is untimely.

These change teams are not close to the work. They can’t possibly craft a change that makes sense for the context of each unique team.

You can easily get too tied to your plans.

In this mode, status reports against the plan are suspiciously “green.” But the “red” truth lurks beneath the pristine status report. Fear of not following the plan or of the plan not being right may drive you to apply optics to status reporting.

All this effort to protect the plan and avoid change is often in vain. Ironically, change is seen as a cost. But without change, budgets are blown and expectations are missed.

The gold standard of success through process improvement is undeniably Toyota:

“The Toyota Way has two main pillars: continuous improvement and respect for people. Respect is necessary to work with people. By “people” we mean employees, supply partners, and customers. The root of the Toyota Way is to be dissatisfied with the status quo; you have to ask constantly, “Why are we doing this?” —Toyota CEO Katsuaki Watanabe

Watanabe’s statement shows the depth and breadth of Toyota’s continuous improvement culture. And it reveals a curious aspect frequently not considered: respect for people. To Toyota, everyone impacted by a change must be considered and included in the change.

You can learn much from Toyota. There is power in their people-oriented, habitual mindset.

Now let’s flip the eight reasons why you might continue doing what you’re doing to adopt a process improvement mindset:

Contexts change. Your customers change, your teammates change, your technologies change, and your goals change.

You have to expect change, be poised to adapt, and meet it head-on. There is no option. If you stand still, opportunity will pass you by.

Embrace change, be ready for it, and don’t fear it. The ability to readily adapt is a competitive advantage. The only risk is not changing.

The best time to change is when you have time to do something to adjust course to hit your target.

Waiting until the end to inspect and adapt is too late. Every interaction you have is a chance to inspect and adapt and meet your goals with quick, easy grace. It looks like this:

The path to an outcome should take many turns.

Predicting the exact path upfront isn’t possible. Take a step, inspect conditions, adjust course, and re-orient to the goal.

While non-intuitive, the shortest path between you and your goal is rarely a straight line.

When you make changing part of your daily routine, changing becomes your habit.

Something you might forget that existing behaviors must stop. Something about what you are doing now isn’t working. Identify what that is and stop it.

Then replace it with the new behavior and practice it instead of the old behavior. Before long, the new behavior will become habitual.

Daily practice makes change a reality.

Co-creation is your path to change success. Don’t roll out a cookie-cutter new process everyone must follow. Instead, you should invite all to take part in its creation.

This requires moving from dictating to partnering. And it involves all affected. It might look something like this:

Don’t assume what worked in the past will continue working.

Even the best routine can improve. Continuous improvement involves a journey towards perfection. So, inspect and adapt everything, whether it results in good or bad outcomes.

Instead of relegating change to a select few, put it in the hands of the masses.

You want those closest to the work to adapt to the conditions in front of them. Build and coach problem-solving capability and authority at all levels of your organization.

Change should not be constrained by limited ownership. Change is everyone’s responsibility.

Change is an investment in your future productivity. The only cost is standing still.

Find ways to invest in change. Build it into the work. Make it a critical aspect of everything you do. Here are a few ideas:

Embracing and celebrating the “red” ensures your problems remain transparent instead of hidden. Assume a “red” condition and invest in learning your way to “green.”

Process improvement, continuously, with respect for people, is critical. Without embracing change, you can’t compete in today’s complex, uncertain context.

Many reasons exist for why you might be averse to change. To recap, here are the eight tactics for embracing a continuous improvement mindset:

What improvements will you make today?

Featured image source: IconScout

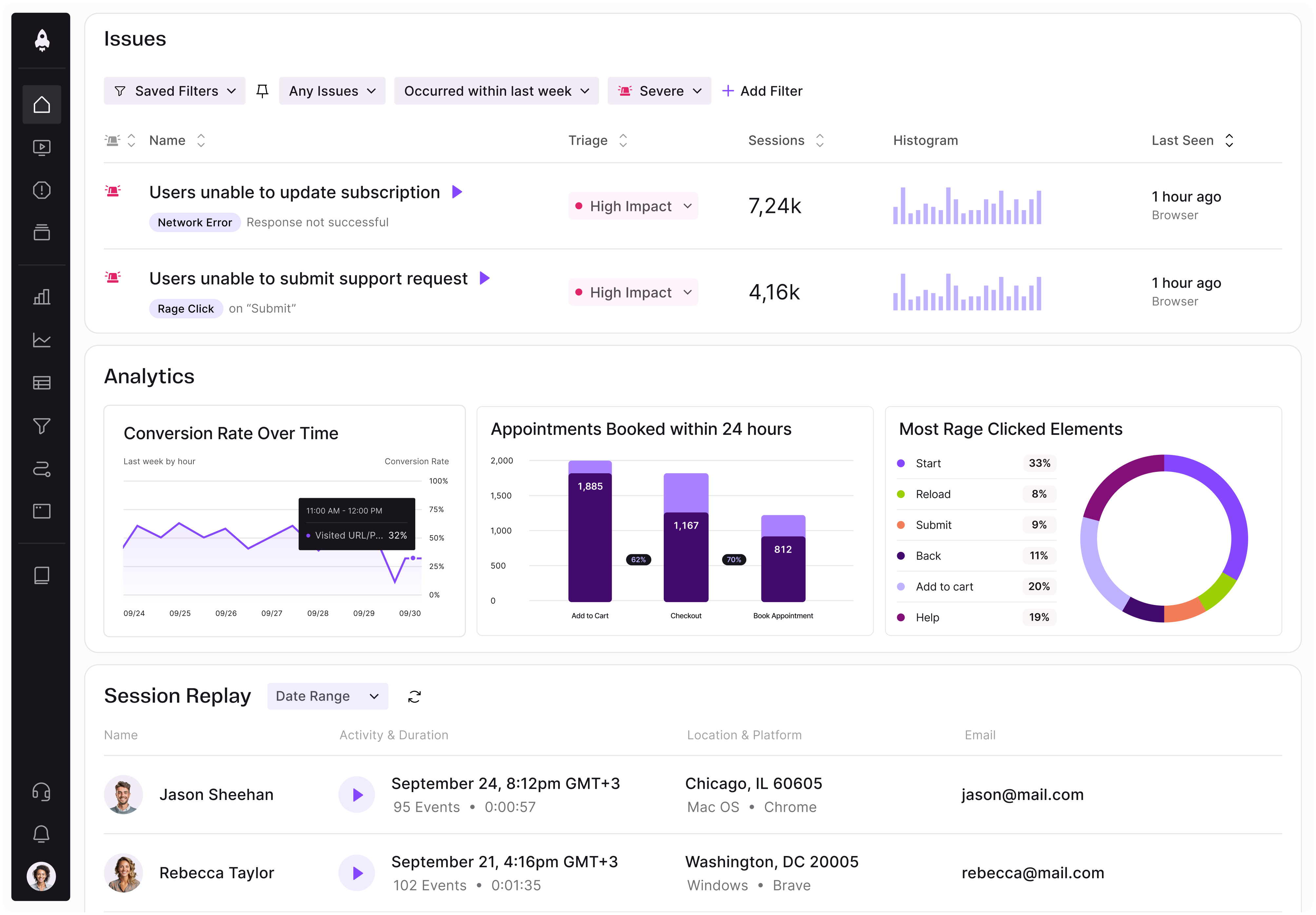

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

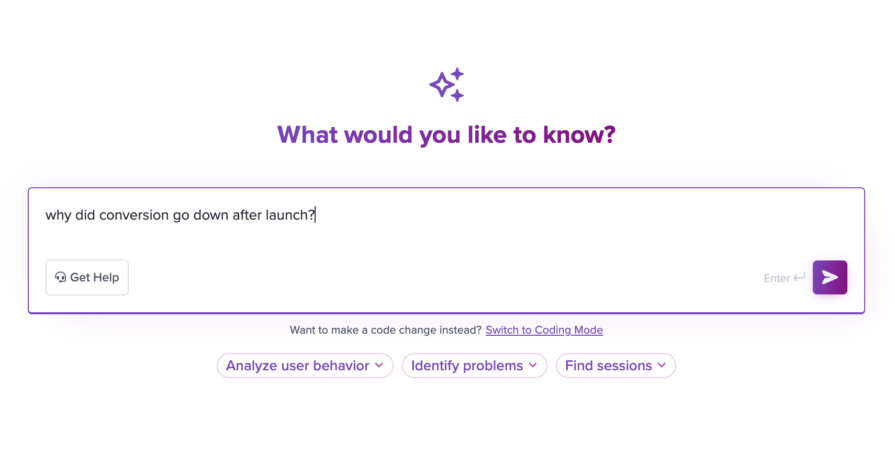

Introducing Ask Galileo: AI that answers any question about your users’ experience in seconds by unifying session replays, support tickets, and product data.

The rise of the product builder. Learn why modern PMs must prototype, test ideas, and ship faster using AI tools.

Rahul Chaudhari covers Amazon’s “customer backwards” approach and how he used it to unlock $500M of value via a homepage redesign.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.