Monika Portman is Associate Vice President of Product Management at Cox Automotive. She joined Cox Auto in 2018, bringing more than 20 years of experience in product management, sales management, and product strategy.

Monika previously held leadership roles at Boart Longyear and Black & Decker. She thrives on developing business strategies and working collaboratively across different functions to reach business objectives.

We recently spoke with Monika to learn more about digital transformation initiatives at Cox Auto and her role within the company. Monika reflected on the unique aspects of driving product management in the technology space and shared insights about the importance of market discovery.

Our conversation has been edited lightly for brevity.

I joined Black & Decker right out of college. At the time, the company’s college hires all started in sales. The training program was designed very intentionally, although I was so new in my career that I didn’t fully understand that at the time.

Reflecting back, getting a start in sales was probably one of the biggest advantages for my product management career. It helped me understand the importance of figuring out what drives customer purchasing decisions, how product messaging can impact sales, and the challenges of selling against the competition.

Then, in one of those typical career conversations with a mentor (who I still keep in touch with), I was encouraged to move into product management. I initially transitioned into an interim role, called channel manager, and focused on individual product readiness — today, we’d refer to it as product ops.

In this role, I was the bridge between the product managers and the sales teams, assisting with ownership of the P&L, creating promotions, and helping make financial decisions.

It wasn’t until I got into the leadership level at Black & Decker that I fully understood the reasons behind those pre-designed career paths. They forced me to learn the product, learn the application, and understand the customer. They also gave me some insight into what sales goes through in order to sell the products that I was creating and developing.

Those early experiences have really influenced how I think about product. Product management isn’t about the technology; it’s about solving problems. It’s not even about solving consumer problems. It’s finding a balance between the stakeholder KPIs and the consumer problems and then coming up with the product and messaging to fulfill both needs.

Creative problem solving. I’ve come up with some pretty crazy solutions out in the field where others have said, “Oh, this is too hard, let’s move on.” To be successful in product management, you need to be curious, creative, and unwilling to walk away from a problem. That’s the chaotic part of working in product — the problems you constantly face.

Yes — it’s actually the one I’m working on right now. We’re less than 30 days away from rolling out a very large transformation initiative. This is probably one of the hardest problems I’ve had the opportunity to help solve in my career, and it’s also the most rewarding because of its difficulty and complexity.

We have an aging software solution that’s similar to an enterprise resource planning (ERP) system on a very old tech stack. The automotive dealership world has its own version of an ERP, usually referred to as a dealer management system.

Over the past 10 years, there have been three to four different attempts to modernize it. It’s gotten to the point where upgrading or adding enhancements for things like automation or data consistency has become more and more difficult.

We kicked this project off two years ago, trying to find a new way to tackle it. I found a creative technology solution that I thought would work, so we ran a POC and got funding. Now, a year after funding, we’ll be live with the software in a dealership group.

Most product lines focus on just one thing, but with an ERP, you have different modules with totally different needs in terms of subject matter expertise.

First, you’ve got the dynamic of accounting and the dynamic of inventory management, and they’re not really related. Then, there’s the ecosystem — there are five different domains that need to be integrated with all of the Cox Automotive solutions.

But probably the most challenging part of the project was figuring out how to interact with all the different parts of the business that run their own brands and are used to living in their own spaces — getting everybody on the same page, working through dependency management, and coordinating roadmaps.

I was in manufactured goods for 20 years but had a strong desire to get into technology. It was hard because there’s a mentality that different industries are completely different from a product management perspective. I didn’t come from a technology background, and I was looking for a leadership position — man, the number of doors that got shut in my face!

Given how difficult it was to move into technology, I thought I’d experience a lot of new learnings and many opportunities for growth. But I’ve found that while my experiences have been different, the problems are absolutely the same.

The difference is that in technology there’s a lot more creative space because everything is a possibility. In manufactured goods, there are built-in constraints, like electricity and load.

Another difference is mechanical and electrical engineers vs. software engineers. They are completely different partners to work with. Software is very creative in nature; the sky’s the limit in terms of how software is written and the problems it can solve.

I’ve only been in technology for five years, but the creativity aspect has been exciting. It’s such an interesting space — almost dangerous to an extent because I tend to throw in the kitchen sink!

What I see with my peers, and with the people I interact with at other companies, is a bit of an “if we build it, they will come” mentality. I’ve been able to add an interesting element to those conversations.

In manufactured goods, where there’s such a heavy capital investment to build anything, I learned early on to rationalize the financial component viability and potential ROI. In technology, there isn’t a significant capital investment except for “hands on keyboard” or human capital.

As a product manager, technology allows you a bit more freedom to do more. It allows you to fail with less risk, which is actually fun because that feeds into experimentation.

But it can also lead to moving forward in an irresponsible way — without actually taking the time to get market feedback. I try to bring to the table the foundational skills that I learned in manufacturing: follow best practices, put the customer first, and understand the stakeholder.

I don’t care what industry you’re in, there’s always a healthy level of friction between product and engineering. What I have found works best is to involve engineering in the solution aspect of things; it’s a team effort. If you simply give engineers a list of demands, you actually stifle creativity.

At Cox Auto, we’re continually working to become more efficient to reduce or prevent churn between product and engineering. We’re trying to implement a process where the product managers do market discovery and identify the problems that we’re trying to solve, but we don’t solve them. As product managers, this is not our nature because we have lots of ideas.

Now, we present the identified problems to our engineering and architecture partners and ask them to come up with solutions. Notice that is plural — we want more than just one solution. Then we discuss and debate and determine the best path forward together.

We try to focus on business outcomes first and then drive some kind of measurement of what that business outcome is. That’s where this bridge from the market needs to the market potential comes in.

We also work closely with our business partners. At Cox Auto, we’re very matrixed. P&L ownership sits with the business. So we’ve got business owners, whether they oversee a brand or a division, that we partner closely with. We also tap into client support, our salespeople, and other internal stakeholders. The collaboration isn’t just between engineering and product.

We look at the list of things we think are important through a lens of, “What can we sell?” Then, we layer that with effort to determine how to sequence the items on the list. Ideally, as part of this process, the less important stuff just falls off.

I personally make a point to have some kind of on-site interaction with our clients at least once per quarter. As part of the discovery process that we’re rolling out, our product managers are strongly encouraged to have at least two touchpoints per week with clients and at least one on-site interaction per month.

About two years ago, Cox Auto implemented human-centered design as a best practice. As part of that initiative, we use multiple tools to capture information.

For example, we highly encourage a lot of whiteboarding experiences. Mural is an example of a platform that we use to pull together all the artifacts of brainstorming sessions. We have templates that we use to consolidate that information and report it out.

As we prioritize and build out our budgets, we try to model the work that we’re doing with our spend for the year. There’s always a carve-out for tech debt to ensure that there’s absolutely no excuse not to address it. Then, in a similar way, we look to our release-trained leaders for their proposed tops-down.

Our final prioritized list is a mix of tech debt or product based off of business value and outcomes. We all align and execute on that. This way, there’s not one product bucket and one tech debt bucket — there’s just one budget.

In terms of hard-and-fast rules, we try to aim for 70/30, where 70 percent of the backlog is tied to product features, and 30 percent is tied to tech debt. Then, depending on what initiatives teams are working on, it’s a negotiating process. We try to identify the outcomes we’re looking to achieve with the budget we have.

In terms of retention, I think it’s really about addressing the big questions that most employees have:

I’ve tried to keep these questions in mind while managing our digital transformation project. We’re T-minus 30 days out from our first code release, so it’s a little intense around here! I’ve been focusing on trying to keep the teams motivated and working really hard, but I try to balance that with making sure everyone is also having fun.

This project has been fascinating but also personally challenging, especially from a team leadership perspective. It’s put my 25 years of experience to the test, and it’s also highlighted growth opportunities for me.

I’ve been fortunate to be surrounded with mentors who have just been phenomenal in helping me work through the areas that I had challenges with. So it’s been pretty career-changing for me in terms of both personal growth and also delivering something big for the business.

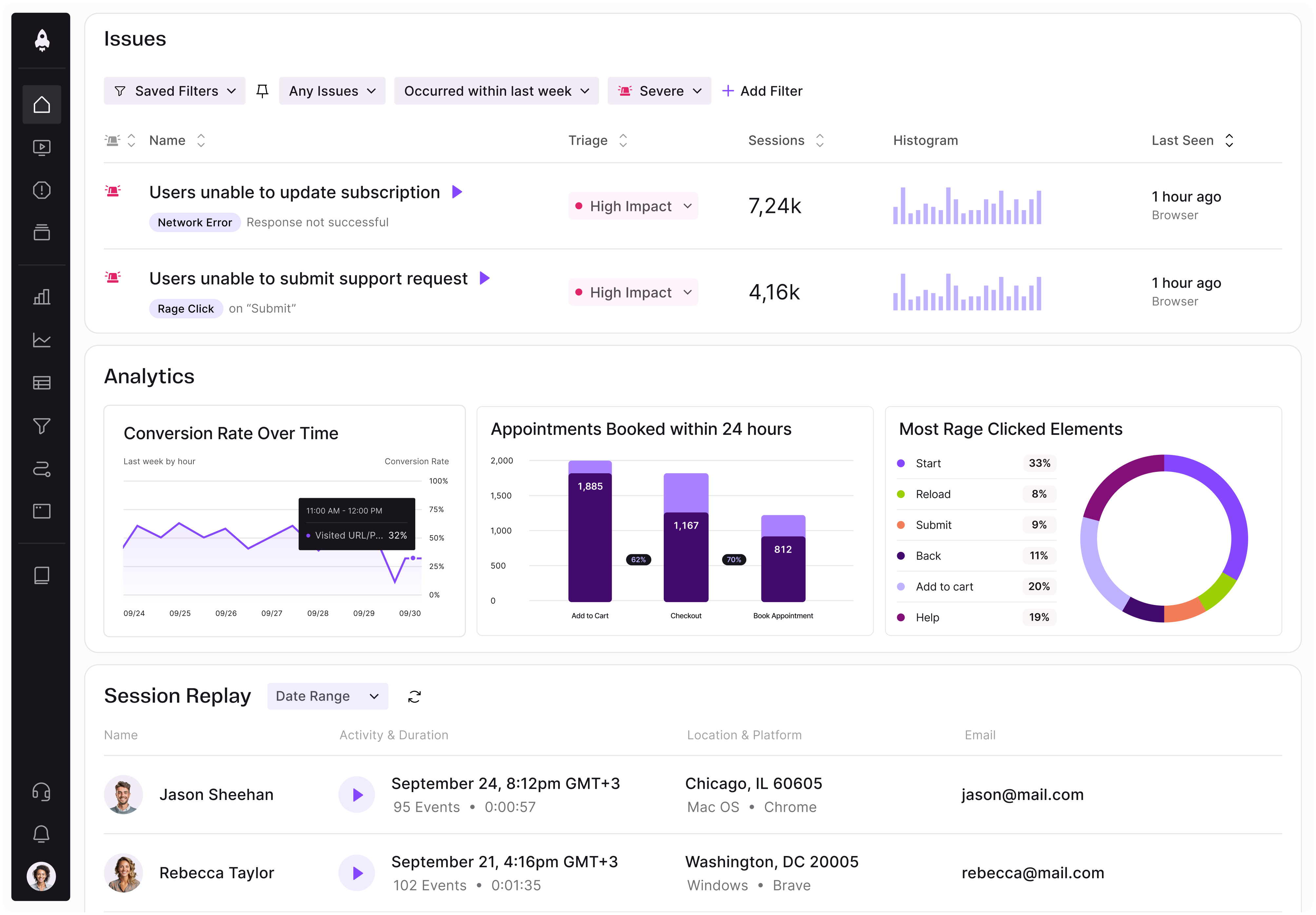

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

Rahul Chaudhari covers Amazon’s “customer backwards” approach and how he used it to unlock $500M of value via a homepage redesign.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.

Maryam Ashoori, VP of Product and Engineering at IBM’s Watsonx platform, talks about the messy reality of enterprise AI deployment.

A product manager’s guide to deciding when automation is enough, when AI adds value, and how to make the tradeoffs intentionally.