Value stream mapping (VSM) is a powerful tool that is used to optimize processes and increase efficiency across various industries.

In this comprehensive guide, we’ll dive into the ins and outs of VSM, including its history, benefits for product managers and examples of successful implementations. We’ll also outline detailed steps on how to conduct a VSM exercise, common symbols used in creating VSM diagrams, and tips for identifying value-adding activities within your processes.

Value stream mapping is a lean tool that documents the step-by-step processes required to bring a product or service to market. It helps visualize, analyze, and improve all the steps involved by identifying waste and reducing process cycle times.

The ultimate goal of VSM is to create more value for customers while improving overall efficiency.

Also known as “material and information flow mapping,” VSM represents the end-to-end flow of goods, materials or information from supplier to customer. It’s often utilized as part of Six Sigma and Lean Six Sigma methodologies for process improvement.

By laying out each step in detail within a process — whether it directly adds value for the customer or supports delivering a quality product — VSM helps you better understanding and more easily identify optimization opportunities.

Value stream was first introduced in 1990 by James Womack, Daniel Jones, and Daniel Roos in their book, The Machine That Changed the World. They later popularized it further through their book Lean Thinking, published in 1996.

However, Toyota had already been utilizing this concept since the 20th century under another name: material and information flow mapping. Toyota engineers found significant productivity improvements could be made by enhancing hand-off activities between steps which could be easily visualized through VSM techniques.

Toyota’s success using lean manufacturing practices helped establish VSM as a widely followed best practice among highly efficient organizations.

Product managers are tasked with the complex responsibility of delivering exceptional products that cater to evolving customer needs. To effectively navigate this challenging role, embracing methodologies and tools designed to enhance efficiency and optimize processes becomes increasingly important.

Value stream mapping (VSM) is one such technique that offers substantial benefits specifically for product managers. In this section, we will explore how VSM supports product managers by increasing process visibility, eliminating waste, reducing time-to-market, promoting stakeholder collaboration, and, ultimately, improving customer satisfaction.

While the exact value stream mapping process will vary from organization to organization (or product to product), the following 7 steps are a good place to start:

A variety of standard symbols are used across industries when creating VSM diagrams — some of which were introduced in 2009 by Lean Enterprise Institute’s “Learning to See” workbook — but these can be modified or expanded upon depending on organizational needs:

| Symbol | Title | Description |

|

Customer/supplier | This symbol can represent a customer or supplier based on its position. When present on the upper right hand corner it represents the customer while if it is on the left-hand corner it represents the supplier. |

|

Dedicated process | This represents a single department,or process with continuous material flow |

|

Shared process | This represents a department, process or operational machine shared by multiple value streams |

|

Data box | This is placed under other icons that require more data for analysis |

|

Work cell | This represents multiple processes integrated into a manufacturing work cell |

|

Inventory | This represents inventory counts that need to take place within the value stream |

|

Manual information | This represents flow from memos, reports or conversation. |

|

Electronic information | This represents digital information flow like the Internet, Intranets, Electronic Data Interchange, etc. Frequency, type of data and the media used can all be recorded |

|

Solution/improvement | The cloud symbol indicates proposed ideas, solutions or suggestions |

|

Expedited | Indicates product or information deliveries that are expedited. |

|

Batched kaban | This icon represents Kanban cards arriving or being sent in batches |

When developing your own VSM template, consider your organization’s unique needs and the specific process being analyzed. Make sure all relevant steps are documented using the standardized symbols described above while also accounting for any industry-specific elements not covered by traditional VSM conventions.

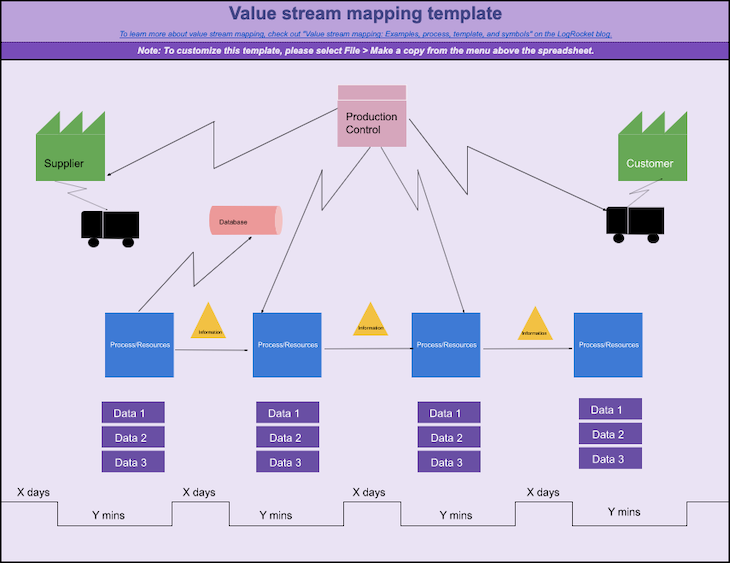

We’ve created a value stream mapping template to help you get started:

Note: To customize the template, first create a copy of the spreadsheet by selecting File > Make a copy from the main menu.

The whole point of value stream mapping is to make your processes more efficient by prioritizing activities that impact desired product outcomes. But how do you actually differentiate between what adds value and what adds up to wasted time?

To determine whether an activity adds value according to lean principles, it must fulfill three criteria:

Value stream mapping offers numerous benefits for product managers seeking to optimize their development processes. By dedicating time and resources to understanding each step within a process, teams can deliver high-quality products faster and with greater customer satisfaction.

With continued practice and implementation of VSM insights, organizations can become more agile, efficient, and successful in meeting consumer demands while staying ahead of the competition.

Featured image source: IconScout

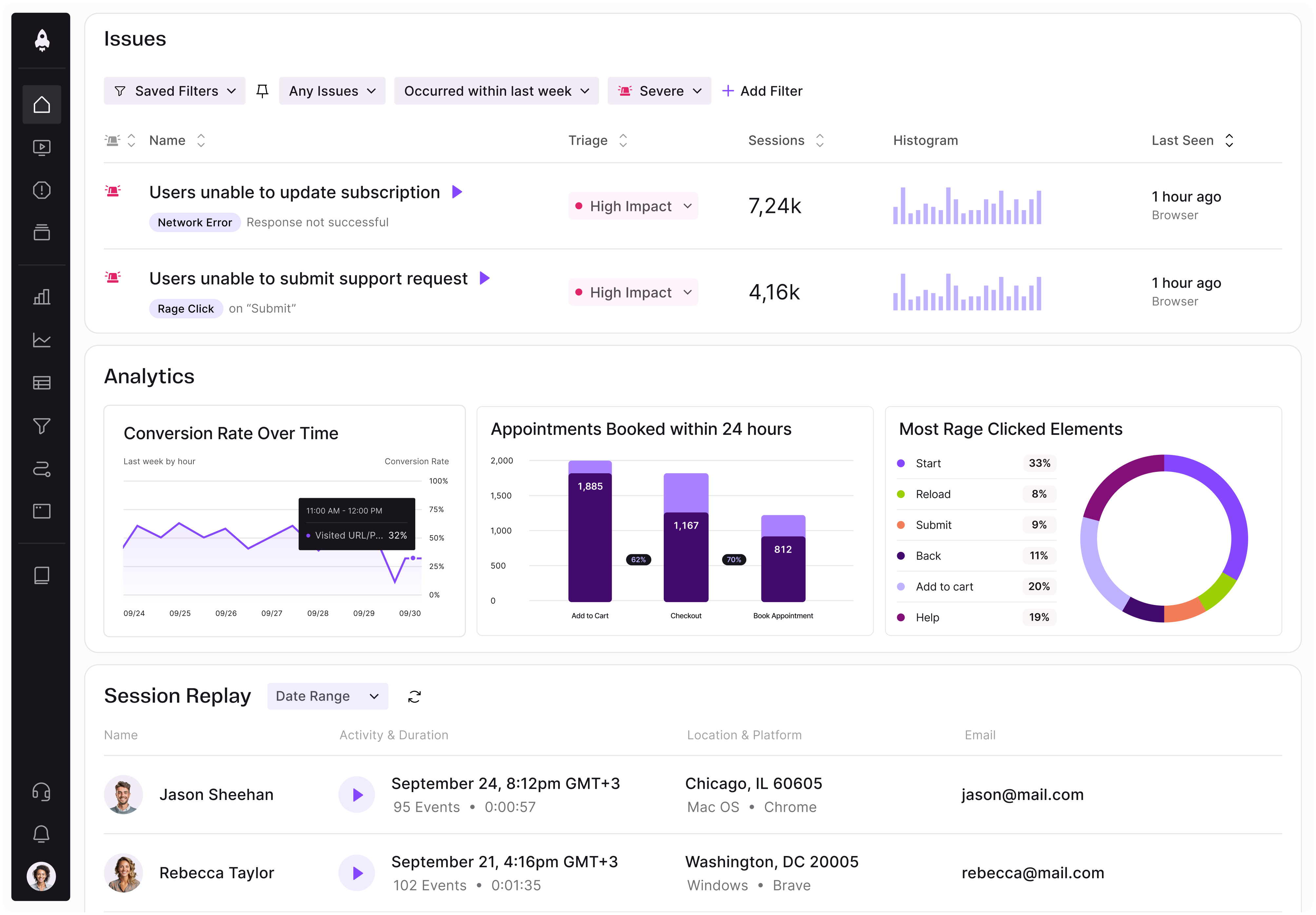

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

Rahul Chaudhari covers Amazon’s “customer backwards” approach and how he used it to unlock $500M of value via a homepage redesign.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.

Maryam Ashoori, VP of Product and Engineering at IBM’s Watsonx platform, talks about the messy reality of enterprise AI deployment.

A product manager’s guide to deciding when automation is enough, when AI adds value, and how to make the tradeoffs intentionally.