As a PM, you know the struggle of balancing product delivery with the best possible outcome. Pressure to keep up with the competition forces the development process to move at a pace that introduces the potential for gaps between customer expectations and iterative deliveries. Because of this, you should focus on implementing a continuous improvement to mitigate product hiccups and prevent future issues from occurring.

The pace of the current development environment requires you to put out products “good enough” to hit the market. These products demand continuous improvements to move closer to the ideal version your customers want. By leveraging continuous improvement, you introduce incremental changes that allow you to gather additional feedback, while minimizing development expenses.

This article provides an overview of the continuous improvement process including its steps, principles, and tools.

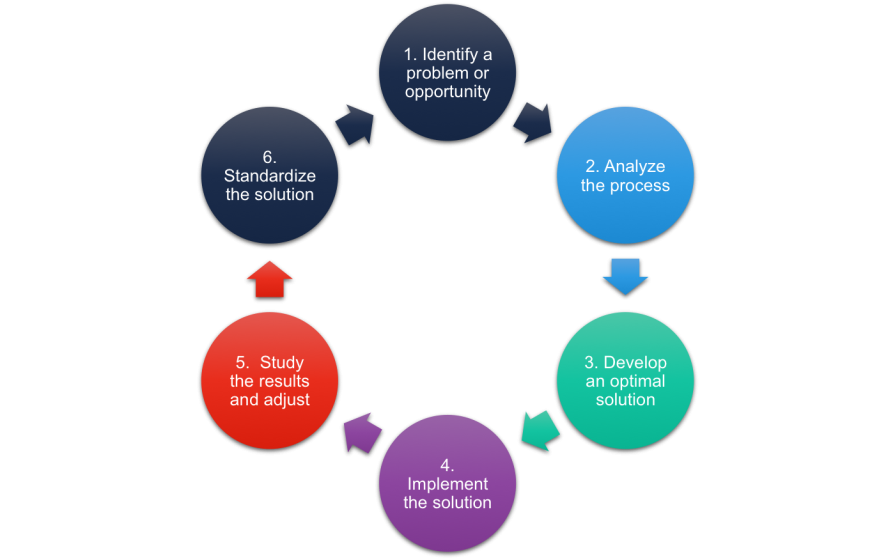

The continuous improvement process (CIP) provides a structured approach to delivering incremental product enhancements. CIP encourages you to identify, define, implement, measure, and analyze the effectiveness of change.

Implementing the CIP involves five key steps. However, always keep in mind the need for data and analytics when implementing these strategies. Without data, teams struggle to identify the right areas of improvement and waste time and resources.

Always have a baseline and goal when addressing a problem. This also gives you a way to measure improvement.

The process requires you to

Alongside the five steps, focus on the following principles to successfully implement continuous improvement in your organization.

With continuous improvement, you always need to focus on the customer. When you understand your customers’ pain points you develop products that address their needs. Look for areas where your product falls short and guide the development team to enhance and innovate your offerings.

By making data-driven decisions, you avoid irrelevant ideas and claims. This also makes the process faster and allows you to validate solutions at a lower cost.

Employees at all levels, whether in product development or customer services, play a crucial role in fostering a culture of continuous improvement. Engaging employees at all levels empowers them to identify issues and propose innovative solutions actively. Their involvement helps to build a culture of ownership, accountability, and continuous learning.

Implementing incremental solutions helps you avoid big decisions based on assumptions. Make sure that you continuously measure the impact of change to ensure data-driven decision-making and focus on areas that require attention.

Improvements need to align with the company’s strategic goals to gain leadership support. Aligning improvement efforts with strategic goals ensures that you efficiently spend resources to add the most value and impact to the business. This approach helps to create a purposeful improvement strategy that benefits individual processes and departments.

Now that you understand the steps and principles of the continuous improvement process, let’s explore various tools and methodologies used in continuous improvement, such as Kaizen, Lean, and Six Sigma.

The specific tool you should use depends on the situation you find yourself in. For example, the Kaizen method might be more suitable when trying to implement CIP in an entire organization. In contrast, the Kanban method can be more beneficial in software development teams.

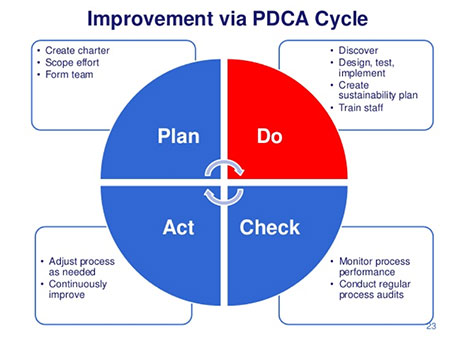

Plan, do check, act (PDCA) (or the Stewart Cycle) provides a streamlined way for you to implement continuous improvement. It works with the following four steps:

Repeat the cycle until you achieve your desired result.

Kaizen comes from the Japanese word for continuous improvement. It originates from the Japanese business philosophy that small changes can create a ripple effect. The Kaizen method focuses on incremental changes that are often easy to implement and track:

The core principles of Kaizen methods are:

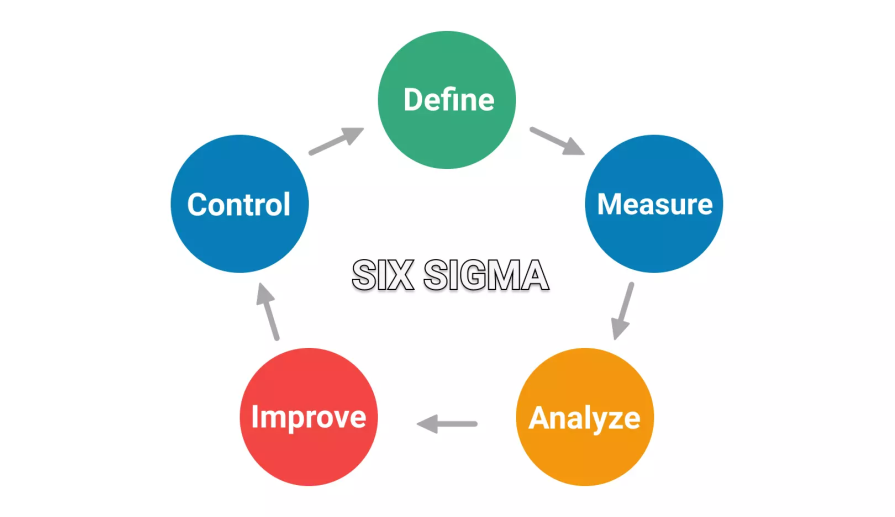

Motorola engineer Bill Smith introduced the Six Sigma concept in 1980. Since then, it has been widely adopted beyond the manufacturing sector. Six Sigma focuses on improving quality by using statistical methods to remove defects:

Six Sigma contains two primary sub-methodologies:

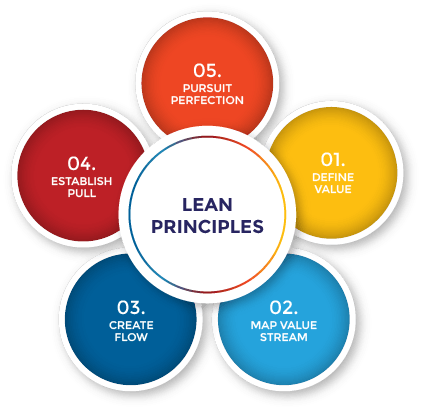

Lean works in conjunction with all the other techniques mentioned above. Taiichi Ohno first introduced lean in Toyota’s manufacturing unit, and since then, it has evolved with new ways of working. Lean principles include identifying value, mapping the value stream, building efficient workflows, developing a pull system, and continuous improvement:

Like any other change, implementing a continuous improvement process in the organization presents challenges. From my personal experience, the hardest thing to overcome tends to be resistance to change and a poor balance between improvement and new development.

At a large-scale organization, most teams work the same way everyday and if you fail to communicate the message effectively, some teams might skip the new flows and processes, creating a chaotic way of working that hinders daily development activities.

Leaders can prioritize communicating the importance of improvement and take time to explain the new process and ways of working to create buy-in from every individual.

Other more practical challenges include having the right tools and techniques in place. For example, there might be data mining in all the flows but no connectivity between the data to conquer any possible problem area identification.

The continuous improvement process (CIP) provides you with a way to stay relevant and competitive. Technology and customer expectations change constantly and fast. Therefore, even if something works flawlessly today, it still needs to be revised with changing times.

When it comes to implementing the CIP, success depends on the acceptability of the people working with the process. The employees at all levels must identify the problem areas and develop innovative solutions that they can drive and take responsibility for the improvement. Empowering people with the right tools and autonomy enables you to create a self-driven process for continuous improvement.

The advancement in analytical tools and technology, such as data mining and process mining, make it almost effortless to identify pain points and find opportunities for improvement. Data and analytics also help create transparency in the organization, further promoting the implementation of the continuous improvement process.

Good luck with your implementation and feel free to comment below!

Featured image source: IconScout

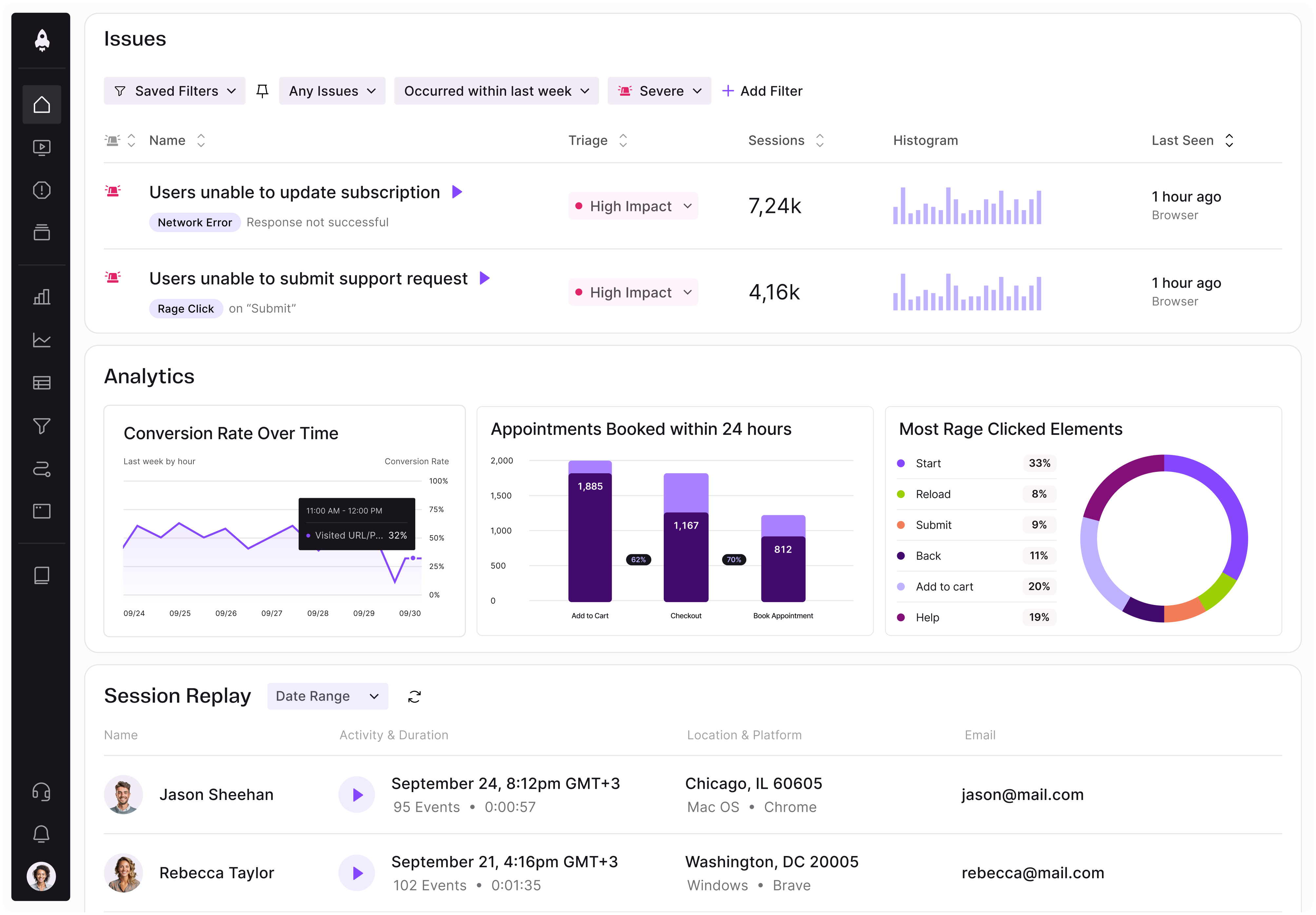

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

A practical guide for PMs on using session replay safely. Learn what data to capture, how to mask PII, and balance UX insight with trust.

Maryam Ashoori, VP of Product and Engineering at IBM’s Watsonx platform, talks about the messy reality of enterprise AI deployment.

A product manager’s guide to deciding when automation is enough, when AI adds value, and how to make the tradeoffs intentionally.

How AI reshaped product management in 2025 and what PMs must rethink in 2026 to stay effective in a rapidly changing product landscape.