You can judge the quality of a product based on the degree to which it aligns with, or exceeds customer expectations. Higher quality products ensure customer satisfaction, enhance your brand reputation, reduce costs, and provide a competitive advantage.

Alongside quality, you also want to make sure that your product demonstrates reliability by consistently functioning over time without failure. Reliability goes a long way in building customer trust and positioning your product.

While these are two separate principles, the Design for Six Sigma methodology brings the two together by embedding them into the product design process from the very beginning. By focusing on customer needs, employing rigorous design techniques, and fostering cross-functional collaboration, DFSS ensures that products are not only high in quality but also reliable and robust, leading to long-term success and market leadership.

This article provides you with an overview of Design for Six Sigma, including its methodology, tools, common challenges, and solutions.

Design for Six Sigma is a product design methodology with a focus on quality and reliability. The design process builds off of Six Sigma techniques, which improve business processes by reducing defects and errors.

Typically, Six Sigma utilizes the acronym DMAIC (define, measure, analyze, improve, and control) to improve a current process that isn’t performing to expectation. DFSS, on the other hand, is used to design new products or processes to meet Six Sigma standards from the beginning.

By designing it right the first time, DFSS reduces waste and improves efficiency. That said, DFSS requires a deep understanding of customer needs and requirements before the design phase begins to ensure the end product does what it needs to do.

DFSS revolves around identifying customer needs, converting those needs into measurable requirements, and looping them in the design process to deliver products that meet customer needs. The core principles of DFSS include:

When it comes to implementing DFSS, DMADV and IDOV are the two most popular frameworks:

DMADV stands for define, measure, analyze, design, and verify. It’s the most popular DFSS methodology and follows a structured process to ensure new products or processes meet customer requirements and Six Sigma standards:

IDOV is another DFSS methodology. It stands for identify, design, optimize, and verify and tends to be used in more complex product or process designs:

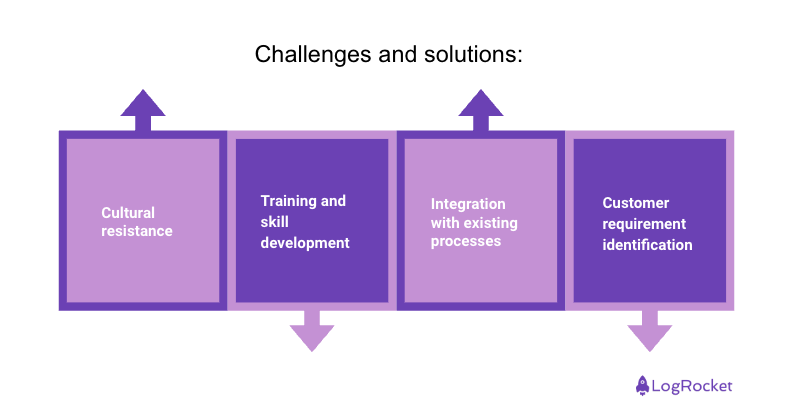

Although DFSS can help you improve your design process, it still comes with its own set of challenges and solutions that you need to be aware of. The most common ones include:

DFSS requires your leadership and team to shift the way they approach design and development. When people become comfortable, they can be resistant to changes that might disrupt the status quo. You might also have a hard time securing buy-in from leadership who could perceive a new framework as additional work.

To mitigate this, try to foster a culture of continuous improvement. Communicate the long-term benefits of DSS by focusing on higher quality, increased customer satisfaction, and competitive advantage. Try to engage with leadership as early as possible in the process.

To successfully implement DFSS, you need people with experience using advanced statistical tools, design methods, and quality management techniques. Training and developing these skills can be costly and time consuming.

Encourage team members to get certified in Six Sigma so they can serve as individual champions. You can also invest in training and self-paced learning courses tailored to the specific needs of your team.

Unless you initially design processes with quality and reliability in mind, implementing DFSS can be very complex. Ongoing projects might be disrupted while you try to shift over.

Before starting, analyze your current process to identify gaps and opportunities where DFSS would most make sense. Additionally, implement DFSS on small scale projects to demonstrate its effectiveness and gain organizational buy-in.

In diverse or rapidly changing markets it can be challenging to identify customer needs and translate them into design specifications. Balancing multiple customer requirements can sometimes be conflicting and difficult to prioritize.

To understand the voice of the customer (VoC), invest in customer research using surveys, focus groups, and customer reviews. Monitor market trends and customer preferences to ensure up-to-date requirements. Use quality function deployment (QFD) to translate customer needs into specific and actionable design requirements

As a product manager, you always want to keep an eye out for areas of improvement, particularly in regards to quality and reliability. To address these, you might have prior experience with or heard people recommend Six Sigma. While Six Sigma can be a great solution, it comes in after you’ve already identified a problem in your workflow.

DFSS helps with this because it implements Six Sigma principles into your design processes from the very beginning. By focusing on customer needs from day one, you can maintain high quality standards and avoid gaps in your product.

Good luck and comment with any questions!

Featured image source: IconScout

LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit your goals.

With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Get your teams on the same page — try LogRocket today.

Great product managers spot change early. Discover how to pivot your product strategy before it’s too late.

Thach Nguyen, Senior Director of Product Management — STEPS at Stewart Title, emphasizes candid moments and human error in the age of AI.

Guard your focus, not just your time. Learn tactics to protect attention, cut noise, and do deep work that actually moves the roadmap.

Rumana Hafesjee talks about the evolving role of the product executive in today’s “great hesitation,” explores reinventing yourself as a leader, the benefits of fractional leadership, and more.